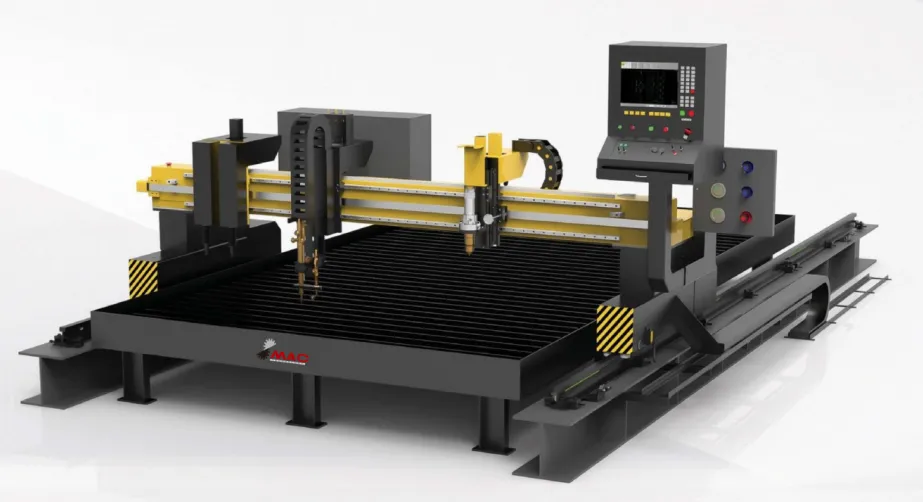

Heavy Duty Plasma Cutting Machine

Heavy Duty Plasma Cutting Machine

General Description

The CNC plasma cutting machine is a brand product of SMAC Intelligent Technology. It adopts a modular design approach, purchases high-quality components, and implements advanced manufacturing processes. With its aesthetically pleasing appearance, low center of gravity, and stable operation, it has become a highly cost-effective product that is widely praised in the industry.

A CNC cutting machine (CNC Cutting Machine) is a device that uses digital programs to drive the movement of a machine tool. As the machine tool moves, the cutting tool that is attached to it performs the cutting operation on the material. This type of mechatronic cutting machine is capable of cutting various materials such as steel plates, stainless steel plates, and copper materials into any desired plane geometric shapes. It performs full-time, automatic, efficient, high-quality, and high-utilization-rate cutting according to the optimized nesting cutting programs provided by the CNC cutting nesting software. The CNC cutting machine represents a modern, high-tech production method and is the result of the integration of advanced nesting optimization calculation technology, computer numerical control technology, and cutting machinery.

Technical Specifications

GANTRY TYPE CNCPLASMA&FLAME CUTTING MACHINE FOR AIR PLASMA

– Specially designed for big size metal plate cutting process.

– Machine size can be produce due to customer’s requirement on X and Y direction. Strong gantry system ensures durability, stability and quick speed.

– CNC controller gives screen off7″, English, Russian, Spanish and others.

– CNC Controller gives easy operation interface, shape library and cutting parameters programs.

– USB terminal is to supporting program and data inputing and outputing.

| Model | ECONOCUT |

| Effective cuttingsize(mm) | 2000x6000mm or customized |

| Cutting model | Plasma and flame |

| 3Dbevel head | Optional |

| Source | Hypertherm PMXor Maxpro200 or customized |

| Maximum speed | 12m/min |

| Positioning Accuracy | ±0.5mm |

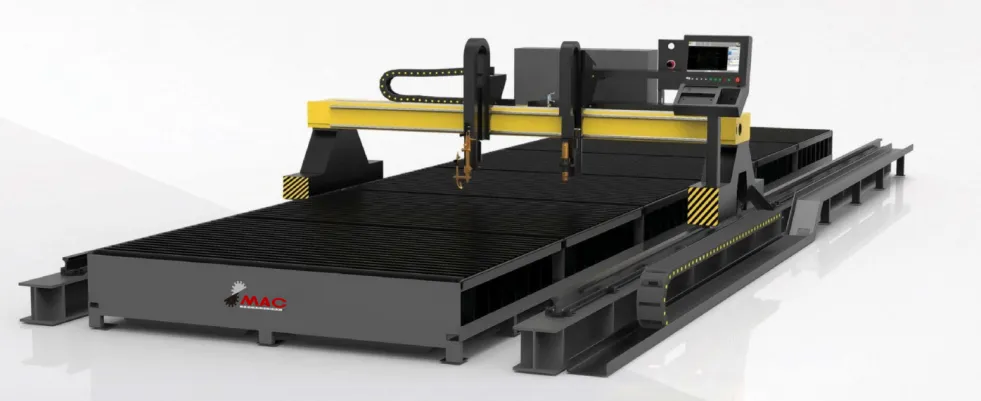

GANTRY TYPE CNC PLASMA &FLAME CUTTING MACHINE FOR HIGH DEFINITION PLASMA

Combine CNC systems, precision machinery, gas technology and plasma technology.

High machining accuracy and high cutting efficiency.

Design of frame is good rigidity, low deformation, high accuracy, strong stability, light self-weight, and small inertia.

Strong driving system achieve higher moving speed and acceleration,

Special design for High definition plasma cutting with True hole technology.

Various customization options such as multi-torch device, Beveling torch device, straight flame cutting torch.

| Model | SMACCUT |

| Effective cutting Size(mm) | 3000X12000mm or customized |

| Cutting model | Plasma and flame |

| 3D bevel head | Optional |

| Source | Hypertherm Maxpro200 orXPR or HPRor customized |

| Maximum speed | 24m/min |

| Positioning Accuracy | ±0.5mm |

HEAVY DUTY PLASMA CUTTING MACHINE FOR ROUND AND HUGE PIPELINE

– It’s a multi axis pipe intersecting line cutting machine with gas cutting and plasma cutting, which can be used in multiple ways.

– Machine frame is processed by heat treatment to keep high accuracy all using life.

– It has the function of combining graphics and data, achieving human-machine dialogue, simple operation, and can be continuously processed for a long time, with stable operation.

– After nesting, Machine can automatically cut the intersecting line related holes and welding grooves of the pipes.

– Widely used in industries such as construction, shipbuilding, power, petrochemicals, metal processing, etc.

| Model | PIPE-IV,v,VI |

| Cutting process | plasmaandflame |

| Pipe diameter | 100-500mm |

| Pipelength | 12m |

| Axis | 3or5 |

| Positioning speed | 6m/min |

| Positioning accuracy | ±0.5mm |

HEAVY DUTY PLASMA CUTTING MACHINE FOR LARGEPIPELINE

– Wide Application Range: The intersecting forms of the intersecting lines are mainly the external branch inside type and the internal branch outside type, and the orthogonal rectangular holes of the main pipe can be realized (the main pipe is orthogonal, the main pipe and the branch pipe and the straight pipe are orthogonal, oblique, and eccentric; Round pipe butt joint (shrimp bend), the round pipe is orthogonal and oblique to the plane, the intersection of the two branch pipes, the intersection of the three branch pipes, the bevel cutting of the “shrimp joint” and other functions covering almost all the cutting needs of pipe fittings.

– High-Precision Control: Adopting advanced numerical control technology, with options of 3-axis, 4-axis and 5-axis, it can precisely control the cutting path and speed, achieving high-precision and high-efficiency pipe fitting cutting.

– High Degree of Automation: It can automatically complete operations such as loading, positioning, cutting, and unloading of pipe fittings, greatly improving production efficiency and reducing labor costs.

– Strong Flexibility: It can adapt to the cutting of pipe fittings of different diameters and different materials, and can also carry out customized production according to customer needs.

| Model | Maxpipe series CNC Intersection Line Cutting Machine(Large Pipe Diameter Model) |

| Outer diameter of pipe | φ800-φ2000mm |

| Maximum load | 15000kg |

| Cutting thickness | 5-80mm |

| Flame cutting speed | 100-750mm/min |

| Plasma cutting speed | 500-2000mm/min |

| Number of control axis | 3/4/5 |