Tube Bending Machine 38CNC

Main features:

|

The frame is assembled in monoblock after welding, it is processed by heating treatment, machining by CNC Floor Boring and Milling center, ensuring the rigidity and processing accuracy of the frame. |

|

|

YUKEN hydraulic system and pump , making sure the machine working stabilization |

|

|

Bending die , clamping die , pressure die , mandrel and wiper die (optional ) , all adopt slow speed wire cut and CNC machine making , the material all adopt 42CrMo , making sure the use life |

|

|

CE standard electrical parts |

|

|

Touch screen setting all parameters , |

|

|

Servo motor bending |

|

|

Workshop photos |

|

|

Name |

Unit |

Parameter |

|

Mild steel round tube |

mm |

¢38*2 |

|

Stainless Steel |

mm |

¢32*2 |

|

Light alloy annealed round tube |

mm |

¢40*3 |

|

Mild steel square tube |

mm |

30*30*2 |

|

Mild steel rectangular tube |

mm |

35*20*2 |

|

Mild steel round solid bar |

mm |

¢16 |

|

Mild steel square solid bar |

mm |

15*15 |

|

Min. bending radius |

mm |

20 |

|

Max. Bending radius(Standard) |

mm |

200 |

|

Head overhang (on bending center) |

mm |

500 |

|

Head height (on bending center) |

mm |

360 |

|

Bending center height (from floor) |

mm |

945 |

|

Max. bar passage inside the P.O.B. positioner |

mm |

50 |

|

Clamping adjustable stroke |

mm |

0-90 |

|

Shouldering adjustable stroke |

mm |

256 |

|

Mandrel retraction adjustable stroke |

mm |

0-76 |

|

Max. Bending Angle |

° |

190° |

|

Though Effective Distance |

mm |

3200 |

|

Bending Speed |

°/sec |

60 |

|

Max. Rotation speed (axis Z) |

°/sec |

200 |

|

Max. Feeding speed (axis X.) |

mm/sec |

1000 |

|

Bending angle Precision |

° |

±0.10 |

|

Rotation angle Precision - axis Z |

° |

±0.10 |

|

Feeding Precision - axis X |

mm |

±0.10 |

|

Turning Servomotor Power |

KW |

0.4(1:28 Reducer) |

|

Feeding Servomotor Power |

KW |

0.75(1:10 Reducer) |

|

System Motor Power |

KW |

4 |

|

Oil Pump Delivery Volume |

L |

14 |

|

Max. Pressure |

Mpa |

16 |

|

L*W*H (Packaging Dimension) |

mm |

4000*700*1300 |

|

Machine Weight |

T |

2 |

|

Name |

Manufacturer |

|

Hydraulic Motor |

Taiwan Guangyuan |

|

Hydraulic Pump |

Taiwan HYDROMAX |

|

Hydraulic Valve |

Japan Yuken |

|

Oil way Board |

Taiwan Shanghong |

|

Cylinder |

Shanghai Jingsheng |

|

Oil tube |

Taiwan SANYANG |

|

Touch screen |

Taiwan Weinview |

|

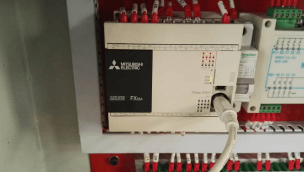

PLC |

Japan Mitsubishi |

|

Turning Servo Motor |

Japan Mitsubishi |

|

Feeding Servo Motor |

Japan Mitsubishi |

|

Angle controller |

Japan Nemicon |

|

Switch power |

Taiwan Mean Well |

|

Contactor |

Taiwan SHIHLIN |

|

Other Electric Parts |

SCHNEIDER,Omron, Taiwan SHILIN |