|

Advanced Equipments for machine body process We use CNC floor type boring machine |

|

|

|

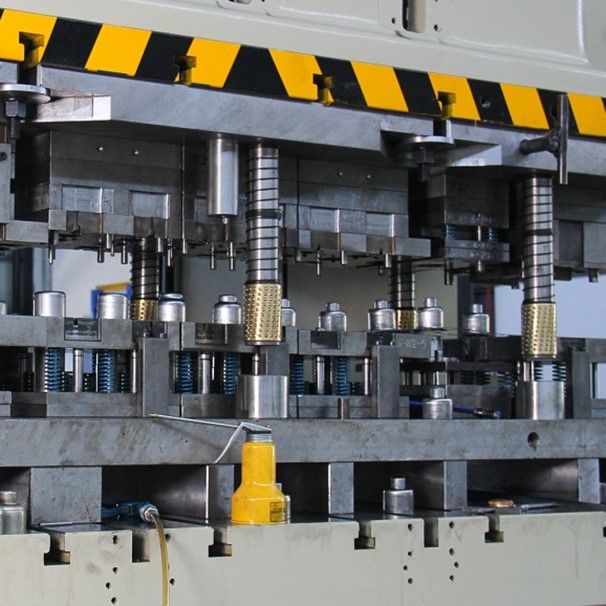

High precision gear, keep the machine running low noise Made by Germany NILE Grinder |

|

|

| For the ram assembly, for every ram we stamp one code, to ensure the assembly quality |  |

|

|

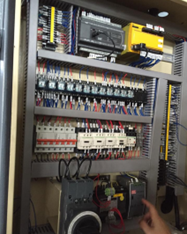

All electrical parts as CSA standard Main Parts (Schneider) Safety module control |

|

|

|

Customer reference in UK Nico Manufacturing Ltd, 109 Oxford Road, Clacton-On-Sea, Essex. CO15 3TJ |

|

|

|

Customer reference in CA Future Steel Buildings Intl. Corp. 220 Chrysler Drive Brampton, Ontario Canada, L6S 6B6 |

|

|

|

Name |

|

APC-110 |

APC-160 |

APC-200 |

APC-250 |

||||

|

Model |

|

V |

H |

V |

H |

V |

H |

V |

H |

|

Capacity |

Ton |

110 |

160 |

200 |

250 |

||||

|

Rated tonnage point |

mm |

5 |

3 |

6 |

3 |

6 |

3 |

7 |

3.5 |

|

Stroke |

mm |

180 |

110 |

200 |

130 |

250 |

150 |

280 |

170 |

|

Stable speed |

s.p.m |

35-65 |

50-100 |

30-55 |

40-85 |

25-45 |

35-70 |

20-35 |

30-60 |

|

Die height |

mm |

400 |

435 |

450 |

485 |

500 |

550 |

550 |

605 |

|

Slide adjustment |

mm |

100 |

100 |

120 |

120 |

||||

|

Bolster area |

mm |

1800*650*130 |

2000*760*150 |

2400*840*170 |

2700*900*170 |

||||

|

Slide area |

mm |

1400*500*70 |

1600*550*70 |

1850*650*95 |

2100*700*95 |

||||

|

Main motor |

kw*P |

11*4 |

15*4 |

18.5*4 |

22*4 |

||||

|

Presses weight |

Ton |

14.2 |

20 |

27.5 |

45.5 |

||||

|

Air pressure |

kg/cm2 |

5 |

|||||||

|

Presses precision |

|

JIS(CNS)1class 一级 |

|||||||

|

Die cushion capacity |

|

Two plate & two cylinders 二板双缸 |

|||||||

|

Capacity |

Ton |

3.6*2 |

6.3*2 |

10*2 |

14*2 |

||||

|

Air pressure |

kg/cm2 |

6 |

|||||||

|

Stroke |

mm |

70 |

70 |

80 |

100 |

||||

|

Die cushion work part dimension |

mm2 |

350*235*2组 |

410*260*2组 |

540*350*2组 |

640*470*2组 |

||||

|

Item |

Brief Description |

|

|

Machine Body |

Basic Parts |

Steel plate welded structure, through vibration aging treatment, the overall heat ageing annealing treatment. (Double aging treatment) |

|

Bolster |

basic parts |

Made from Casting HT200, through annealing treatment |

|

Crank |

Basic Parts |

Made from Forging, through flaw detection, surface quenching, nitriding processing |

|

Fly Wheel |

Basic Parts |

Casting HT200, Through Annealing Treatment |

|

Worm |

Basic Parts |

Zinc-based alloys |

|

Worm Gear |

Basic Parts |

Made from 45# steel |

|

Connecting Rod |

Basic Parts |

Made from Ductile iron, cast iron, and through normalizing treatment |

|

Ball Head and Screw |

Basic Parts |

Made From 45# steel, surface by Nitriding treatment |

|

Balance Cylinder |

Parts |

Cylinder Body Inside Through Honing Processing |

|

Machine body |

Steel metal machine body, iron cast working table |

|

Gears |

Forging die gear grinding with Germany N1LES grinding machine; |

|

Inverter |

TECO ( Taiwan ) |

|

Motor ` |

TECO ( Taiwan ) |

|

Double-solenoid valve |

TACO ( JAPAN ) |

|

CLUTCH |

OMPI ( Italy ) |

|

Over-load protector |

KINGAIR ( Taiwan ) |

|

Bearing |

NSK ( Japan ) |

|

Oil seals |

NOK ( Japan ) |

High performance dry clutch & brake

Standard operating system of kiston

Operation mode selection/off/inching

Safety one stroke /continuous

Hydraulic overload protector

Overrun detector

Dual solenoid valve

Missfeed detector

Motorized slide adjustment

Digital die height indicator(unit 0.1mm)

Motorized grease pump

Total counter,6 digits

Preset counter,6 digits

Maintenance counter,4 digits

Life counter ,6 digits

Electronic rotary cam switch(6 spare channel)

Air ejector 1/2" one channel

Air source receptacle 1/2" two channel

Missfeed detection circuit

Power receptacle(available only for single phase

110V power source wiring by user)