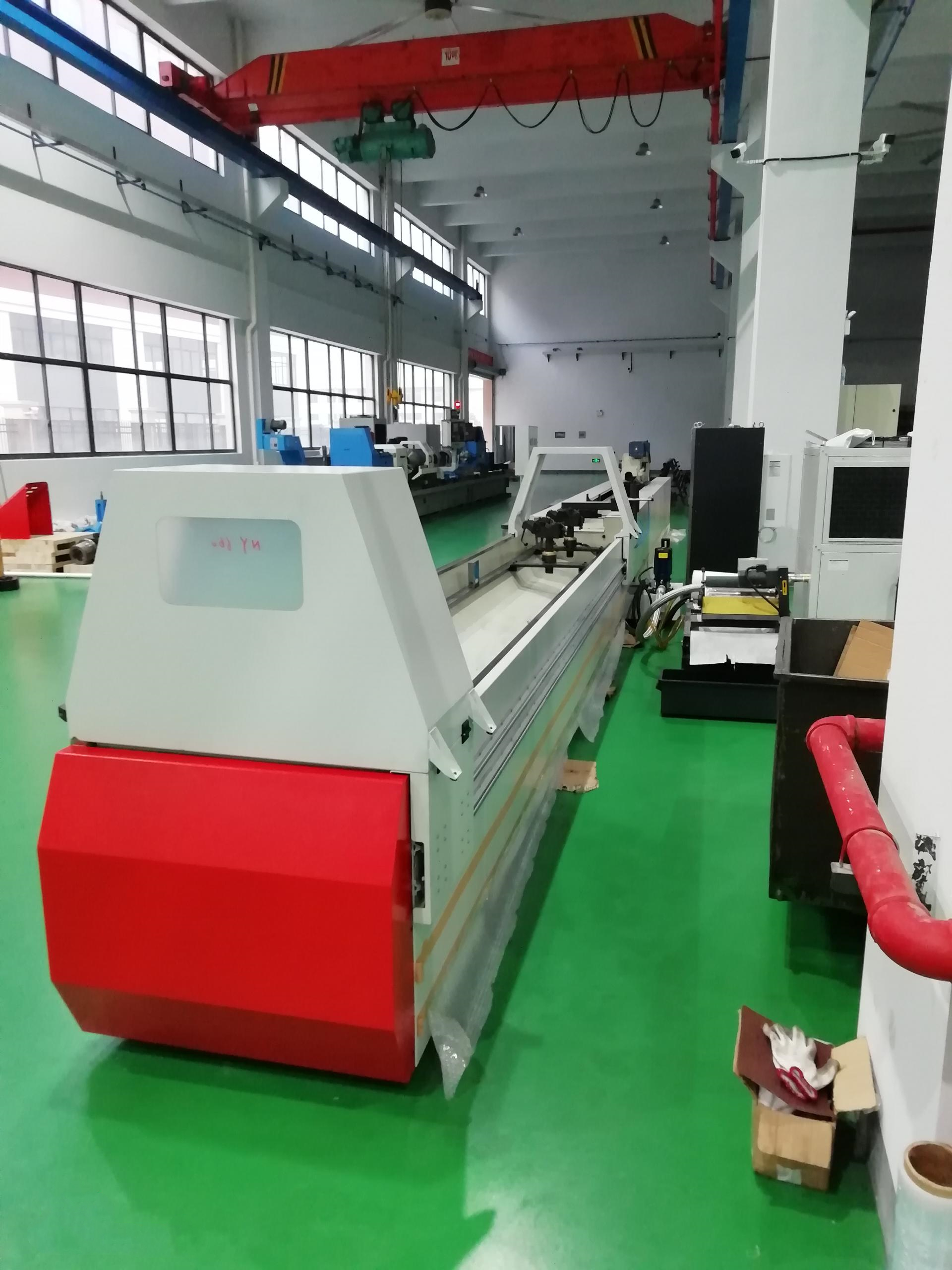

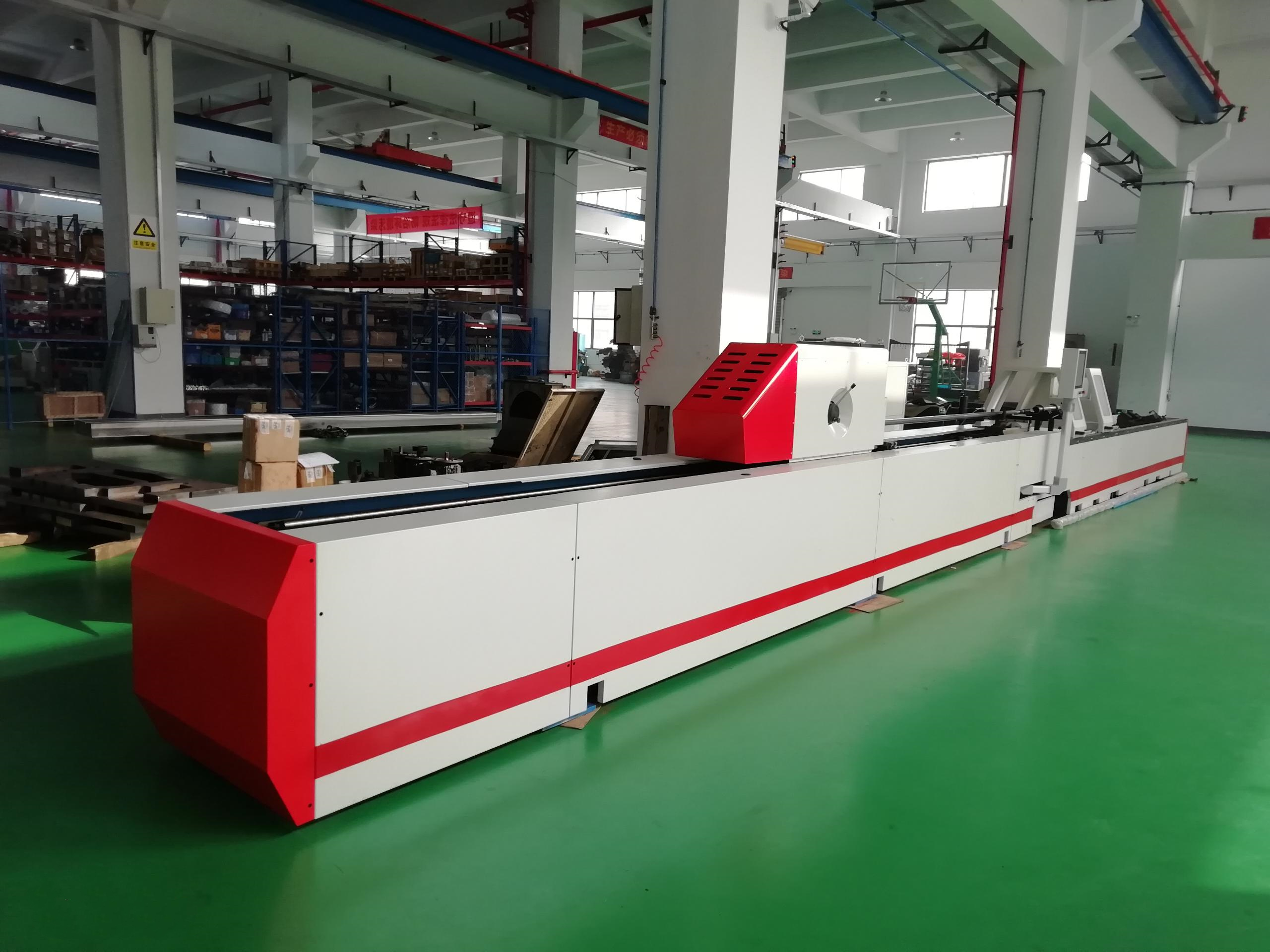

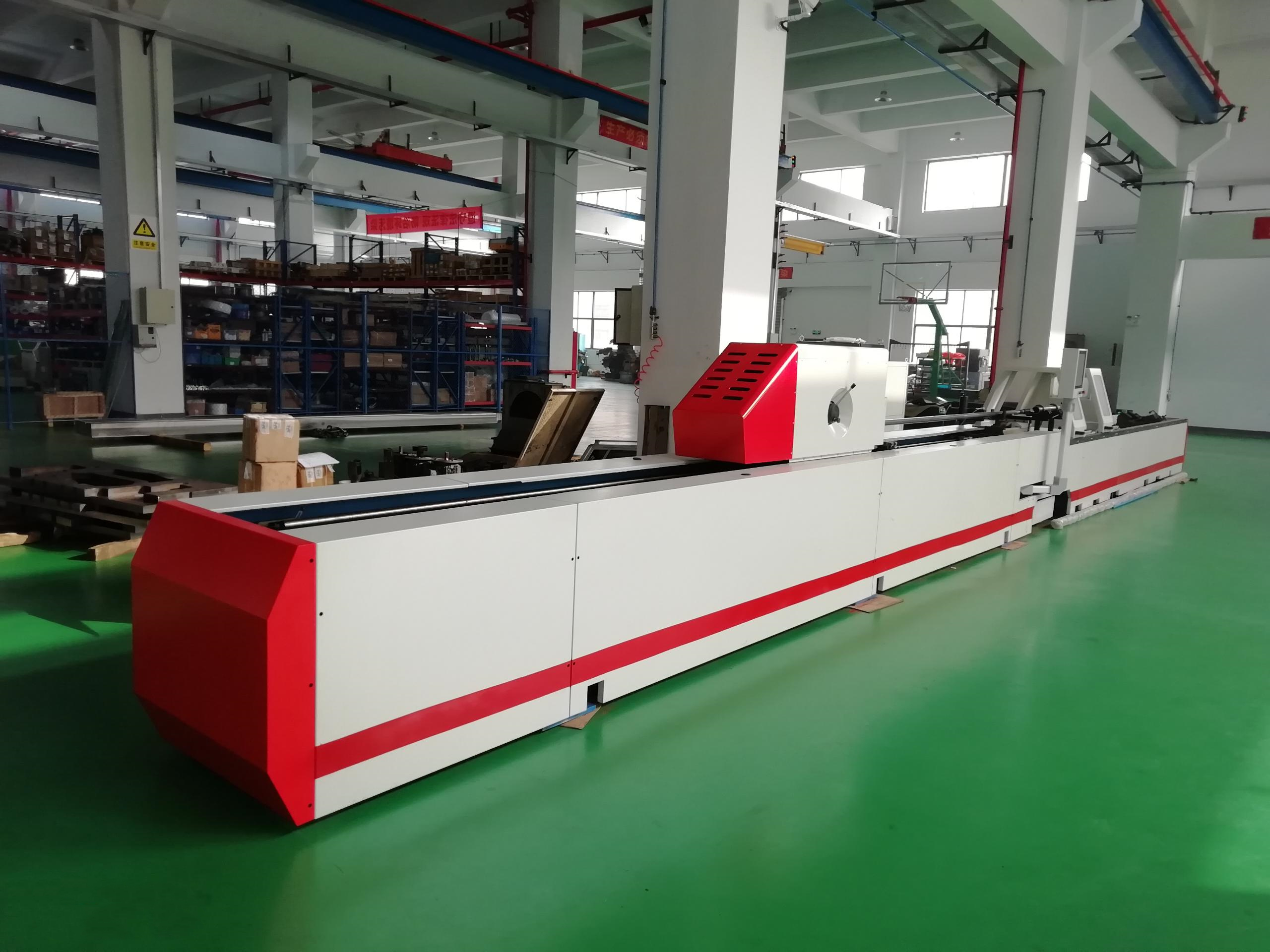

Deep Hole Drilling Machine KT60-1500

- Machine Bed

Cast iron machine bed with heavy rib, treated with annealing for relieves of internal stress, box way design. Integrated with two flat guide ways for both high stability and precision guiding.

- Work piece Headstock

Work piece headstock mounted on the end of machine bed. The spindle driven by A.C. motor and gear box.With forced lubrication unit for spindle bearing.

- Lantern Flange and Manual 4-jaw Clamping Chuck

The Lantern Flange is mounted on the spindle nose of work piece headstock, for the reception of clamping cone or clamping chuck, also with 2 square holes for chips and coolant exhausting.

- Work Piece Steady, closed type

Suitable for rotating pieces, with three concentric rollers, complete with bearings. Upper side can be opened for an easy piece introduction.

- Work Piece Steady, open type

Having two supporting rollers, manually operated by operator.

|

Machine Type |

KT50-1000 |

|

Working method |

Counter rotation between work piece and boring tool |

|

Drilling method |

BTA solid drilling |

|

Drilling Capacity |

|

|

Solid Drilling |

Ø 18 – 50 mm |

|

Drilling depth |

Max. 1000mm |

|

Clamping Length |

Max. 1000mm |

|

Machine Specification |

|

|

Width of bed guide way |

500 mm |

|

Centre height from guideway |

250 mm |

|

Work Piece Headstock |

|

|

Motor power |

15 kw, dual-speed spindle motor made by MK |

|

Spindle speed |

Max. 1000 rpm, infinitely variable |

|

Boring Headstock |

|

|

Motor power |

22 kw, dual-speed spindle motor made by MK |

|

Spindle speed |

Max. 2000, infinitely variable |

|

Boring Carriage |

|

|

Z axis servo motor drive |

4.3 Kw, 20.5Nm |

|

Rapid movement speed |

2000 mm/min. |

|

Feed Rate |

5-500 mm/min. |

|

Oil Pressure Head |

|

|

Contacting Stroke |

150mm |

|

Thrust force |

20KN |

|

Work piece Support |

30 – 150 mm |

|

High Pressure Pump |

|

|

Delivery rate: |

120 L/min. |

|

Pressure |

Max. 60Bar |

|

Drive power |

18.5Kw |

|

Filtration Accuracy |

50μm |

|

Drilling Accuracy |

|

|

Roughness |

Ra 0.8-3.2 |

|

Hole Deviation at exit |

0.50mm/1000mm |

|

Straightness |

0.10mm/1000mm |

|

Power Supply |

|

|

Power Voltage |

380 Volts, 3 Phrase, 50 Herts |

|

Control Voltage |

24 Volts ,DC |

|

Connected power |

55Kw |

|

Total weight of machine |

|

|

Machine Size |

|

|

|

|

|

Floor Space |

Appr. L12,000 mm × W 2,800 mm × H2,200 mm |

|

Total Weight |

Appr. 12,000 Kg |

|

1.1 |

BTA counterboring head dia.60.5mm, |

|

1.2 |

Carbide Indexable inset |

|

1.3 |

Carbide guide pad |

|

1.4 |

Fiber guide pad |

|

1.5 |

Boring bar OD51×L8000 |

|

1.6 |

Boring bar Accessories package (bush, sealing, supports) |

|

1.7 |

Clamping cone |