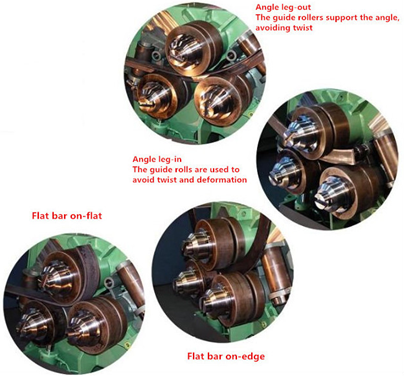

The machine is an efficient processing machine which is specially designed to bend I steel, U steel, flat beam, solid bar, etc. It has three working rollers, and the positions of the two bottom rollers can be adjusted along the arc. Assisting rollers are installed on both sides of the machine to control the work quality in the bending of proportional steel sections. The machine is reliable to operate with various functions and is an ideal bending machine that's adjustable and able to deal with different types of materials and specifications only by recombining the die settings. This removes the need to change dies. The machine offers high flexibility and reliability at a low cost.

|

Model |

W24Y-500 |

|

|

Yield limit |

≤245 |

|

|

Minimum beading Dia (Angle steel leg out) |

300-400mm |

|

|

Main Motor |

2.2/2.2KW |

|

|

Dimension / Weight |

1200*750*1580mm / 900kg |

|

|

Capacity |

Angle iron |

50*50*5 Φ350mm |

|

Square tube |

30*30*2.5 Φ350mm |

|

|

Square tube |

40*40*2.5 Φ400mm |

|

|

Round tube |

2” (t=3) Φ450mm |

|

|

Flat steel |

50*6 Φ350mm |

|

|

Square steel |

18*18 Φ350mm |

|