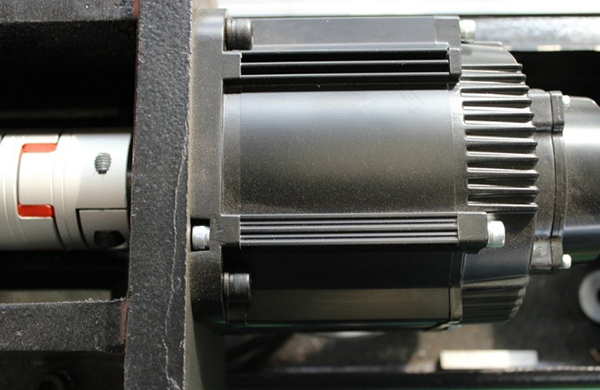

Adopts Siemens 808D special CNC system and matches up digital AC servo motor to make it fast

and reliable;

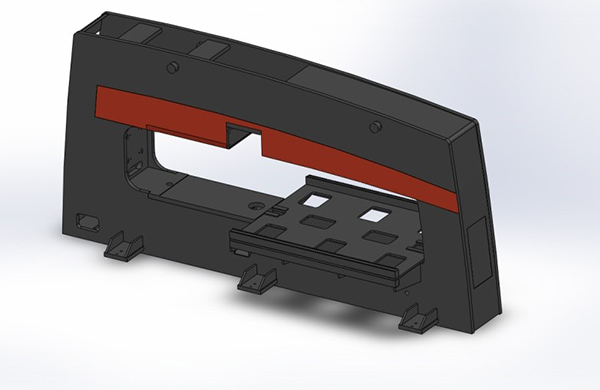

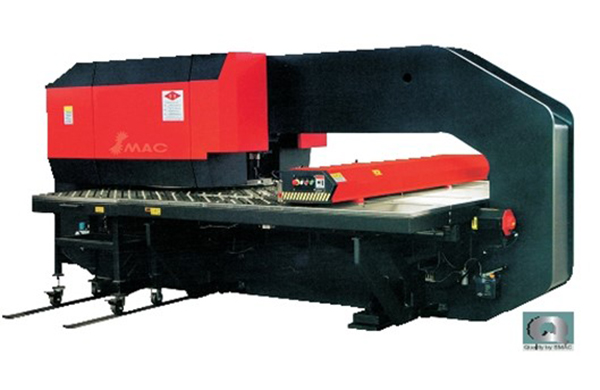

Press is O type steel welding, the whole pass by tempering treatment to own good rigid and

hardly deformation;

The stroke can be adjustable; a reliable drive system can select the stroke automatically

corresponding to different thicknesses of metal sheets;

With the second positioning function, can achieve processing without a dead zone;

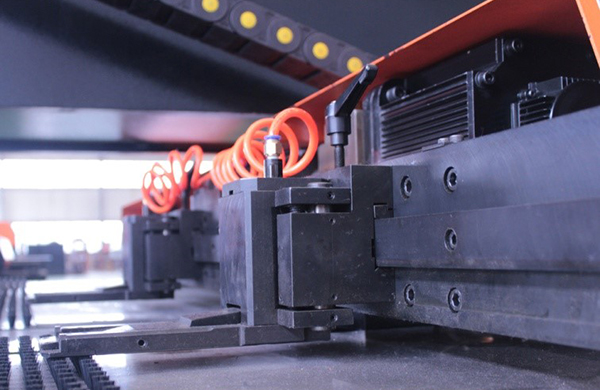

The transmission system use the international brand with high precision, big guide the ball

screw, linear guide rails are high precision and good performance;

Main pneumatic components, electric components and transmission adopt well-known parts,

which makes the stamping work perfectly; Imported pneumatic components guarantee

reliability of the machine;

Centralized lubrication device provides lubricant oil to the desired points to reduce friction

of pairing elements, to improve service life.

Process:

Machining program preparation (automatic computer programming)→machining program

input control system (cable transmission, U disk transfer)→sheet metal manually feeding→

workpiece positioning→clamps clip sheet→feeding positioning (precision ball screw servo

drive )→stamping→stamping completed to unloading location→Clamps Loosening sheet→

manually unloading and palletizing→waste output.

Second positioning function

Equipped with a second positioning function, can achieve without dead zone processing. Enhance productivity, and save the plate and costs.

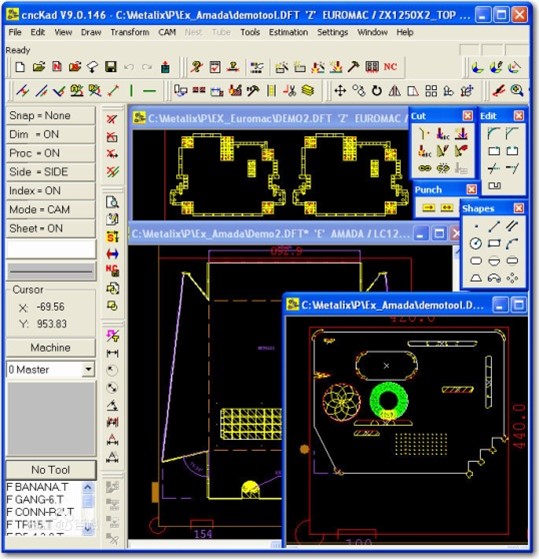

Match up CNCKAD CNC punching machine special software, CAD program can transform to program code via CNCKAD, AUTOCAD and CNC program achieve perfect butt.

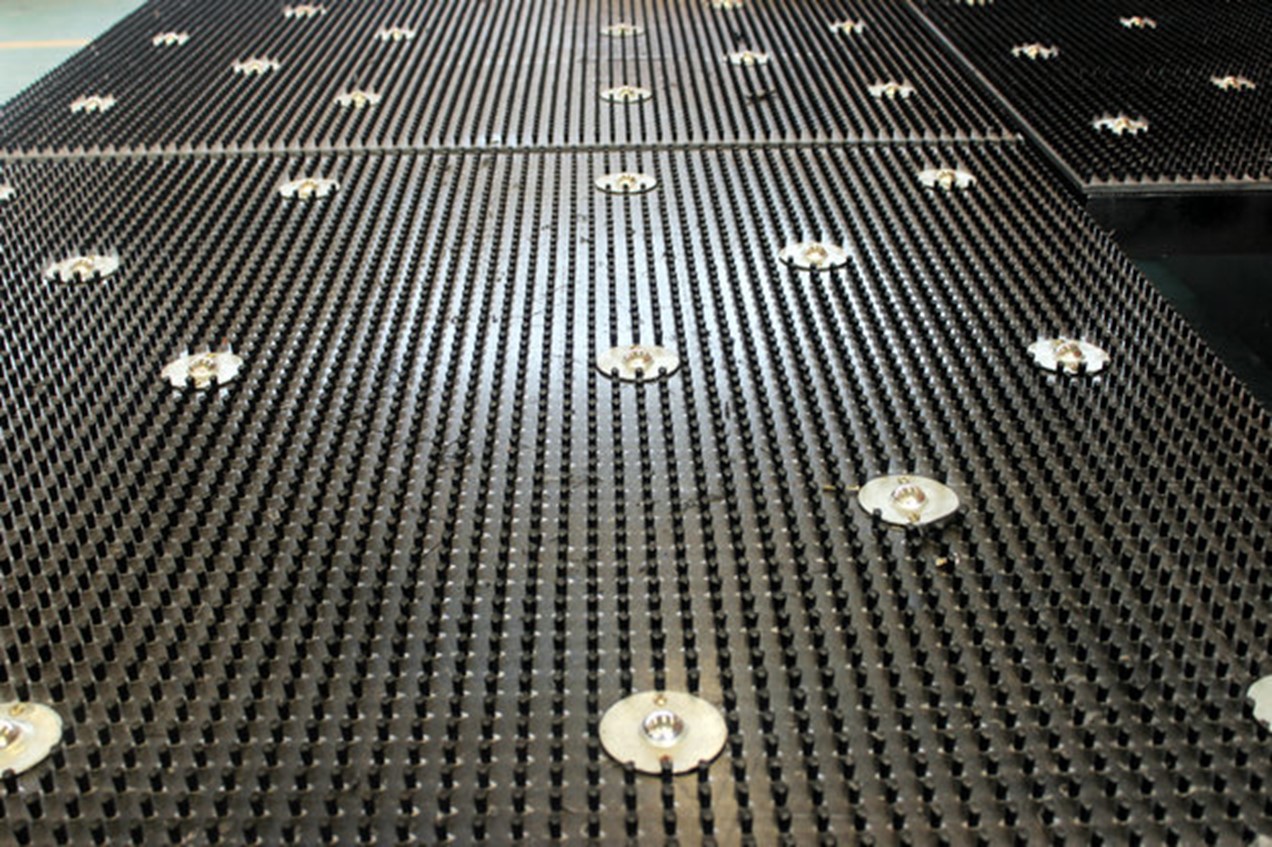

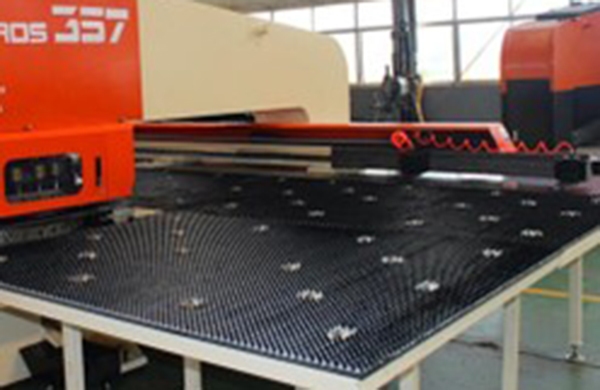

Feeding platform

Workbench adopts hard brush, can reduce noise and vibration and can protect surface of the plate;

Big interval between lathe ultra wide guide rail. Big lathe span, horizontality and support performance are better. Fully ensure the accuracy of processing large plate, under the condition of high speed feeding more balance;

Integrated design of auxiliary and main platform, the auxiliary platform can move around with plate, Reduce 30% of the friction force between the plate and brush platform;

Automatic centralized lubrication system

All lubricating points can realize automatic centralized lubrication. Reduce movement noise, enhance machining precision, and effectively prolong the service life of the equipment.

|

Welded O type press |

Siemens 808D CNC system |

|

|

|

Hydraulic station |

Siemens Servo motor |

|

|

|

Ball screw |

Linear slider |

|

|

|

Pneumatic floating clamp |

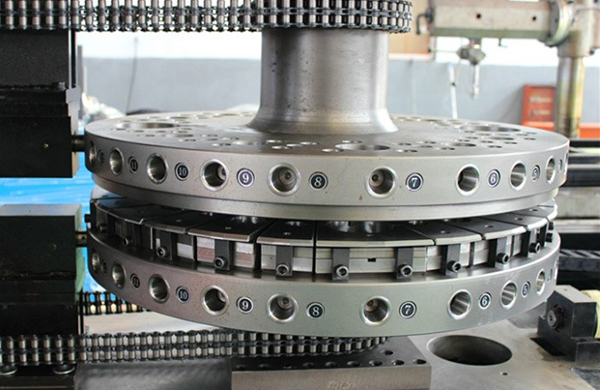

Standard turret |

|

|

|

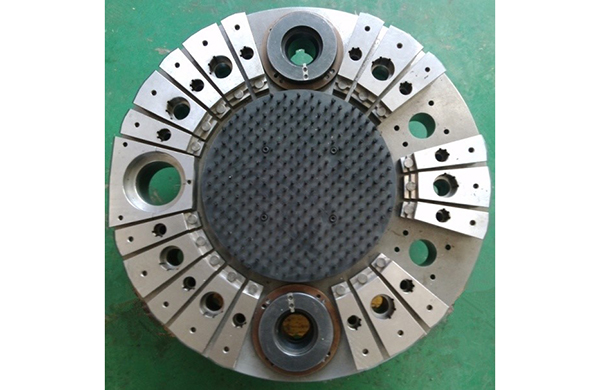

Standard mold base |

Feeding platform |

|

|

|

Specification |

Unit |

HP-H300 |

|

Transmission mode |

/ |

Hydraulic |

|

Punch Force |

KN |

300(30T) |

|

Power Rating |

KW |

18.2 |

|

Max. Processing Size |

mm |

1500 *3000(Re-position to 1500*6000mm) |

|

Max. sheet Thickness |

mm |

≤6(according to hole diameter) |

|

Max. Punch Diameter |

mm |

Φ88.9 (D station) |

|

Max. Traversing Speed |

m/min |

60 |

|

Max. Punch Hit |

hpm |

600 |

|

Hole Accuracy |

mm |

±0.1 |

|

Number of stations in turret |

No. |

32 |

|

Turret Speed |

rpm |

30 |

|

Controlled Axis |

No. |

4 |

|

Auto Index |

NO. |

Included |

|

Air Pressure |

mpa |

≥0.8 |

|

Outline Dimension |

mm |

4490*5300*2110 |

|

Machine Weight (About) |

T |

11.5 |

|

Item |

Model-Part Number |

Manufacturer |

|

|

CNC System |

808D |

SIEMENS |

|

|

Servo Motor |

|

SIEMENS |

|

|

Breaker |

|

Schneider |

|

|

Contactor |

|

Schneider |

|

|

Relay |

|

OMRON |

|

|

Proximity Switch |

|

OMRON |

|

|

Programming Software |

CNCKAD |

As gift |

|

|

Hydraulic system |

|

Nanjing Qiwei |

|

|

Transmission Parts |

|

||

|

Linear slider |

|

Taiwan HIWIN |

|

|

Ball screw |

|

Taiwan TBI |

|

|

Ball screw Support Bearing |

|

Japan NSK |

|

|

Supporting Bearing for Turret |

|

Japan NSK |

|

|

Wheel Bearing |

|

Japan NSK |

|

|

Main Transmission Bearing |

|

Japan NSK |

|

|

Pneumatic Parts |

|

||

|

Three joints |

BFL3000 |

AIRTAC/SMC |

|

|

Electromagnetic Valve |

|

AIRTAC/SMC |

|

|

Magnetic Switch |

|

AIRTAC/SMC |

|

|

Coupling |

|

Japan NSK |

|

|

No. |

Name |

Size |

Quantity |

|

1 |

Air tube |

Ø8 |

5 meters |

|

2 |

Air tube joints |

Ø8 |

5 pieces |

|

3 |

Oil tube joints |

Ø6 |

5 pieces |

|

4 |

Anchor bolt |

M24 |

1 set |

|

5 |

Scrap car |

Factory standard |

1 unit |

|

6 |

Socket head wrench |

M1-M12 |

1 set |

|

7 |

Clamp jaw |

|

2 pieces |

|

8 |

Clamp handle |

|

2 pieces |