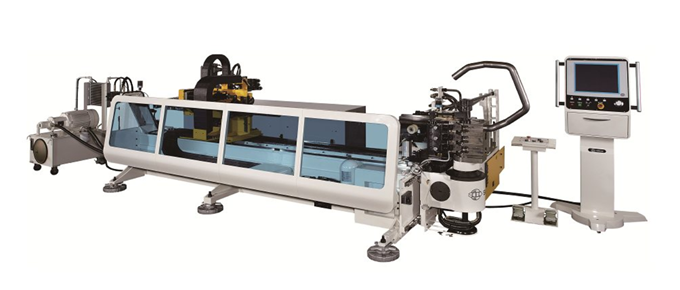

Tube Bending Machine 5 Axis

description1

Zipper closure

1/5 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the

body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them

in

place during workout

Product Features

SB-66X5A-3S-SR (+2C) tube bender is special for Booster and 1D Bending. The tube bending capacity up to O.D.63.5mm, this line of booster benders fulfills all needs for the manufacturing of exhaust systems for cars, motorcycles, trucks and buses.

- Ability to make 1D Tube Bending + Draw tube bending in the same tube bender

- Electric Servo Bending or Hydraulic Servo Bending

- May use from 1 ~ 6 bending stacks, applicable for complex, bend-in-bend parts

- On electric benders, uses SOCO patented DGT ( Direct Gear Transmission ) system for maximum bending efficiency and precision, minimizing transmission points and interference

- 2C - SOCO DBS Cutting System ( Double Blade Shear ) – Option for full automation and minimal cutting deformation, as well as smallest cutting radius to minimize waste between bends ( optional )

- May program up to 4 different parts for Bending + Cutting on the same tube

- May use Internal or External collet system ( optional )

- Built-in internet connection and self-diagnostics

- May be connected to SOCO Automatic Loading + Unloading Systems

- May be connected to the SOCO i-Report System for tracking and generating production statistics ( optional )

- IB – Interference Zone Booster for short pieces ( Optional )

Configuration

| The frame is assembled in monoblock after welding, it is processed by heating treatment, machining by CNC Floor Boring and Milling center, ensuring the rigidity and processing accuracy of the frame. |  |

| YUKEN hydraulic system and pump , making sure the machine working stabilization |  |

| Bending die, clamping die, pressure die, mandrel and wiper die (optional ), all adopt slow speed wire cut and CNC machine making, the material all adopt 42CrMo , making sure the use life |      |

|

CE standard electrical parts Mitsubishi PLC control Schneider electrical parts |

|

|

Intermediate control machine(IPC) ( bending degree , feeding length , rotating degree ) Manual /semi auto /fully auto working model Chinese /English language |

|

|

Servo motor bending This is optional , usually , only use hydraulic cylinder driven the bending , if you looking high speed with high precision , we suggest the servo motor ( Mitsubishi servo motor ) |

|

| Workshop photos |  |

Machine Whole Pictures