Gantry Type CNC Plasma Cutting Machine CNCSG3000

1 Model: CNCSG3000 plasma cutting machine

2 Basic Components

|

Mechanical Components |

CNC plasma cutting torch |

1set(Kjellberg) |

|

Plasma torch height controller |

1set |

|

|

Plasma torch anti-collision device |

1set |

|

|

Drive Model |

Double-side |

|

|

Cable/hose Supply Model |

Pedrail |

|

|

Electronic Components |

Numerical control system model |

LKNC-3200 |

|

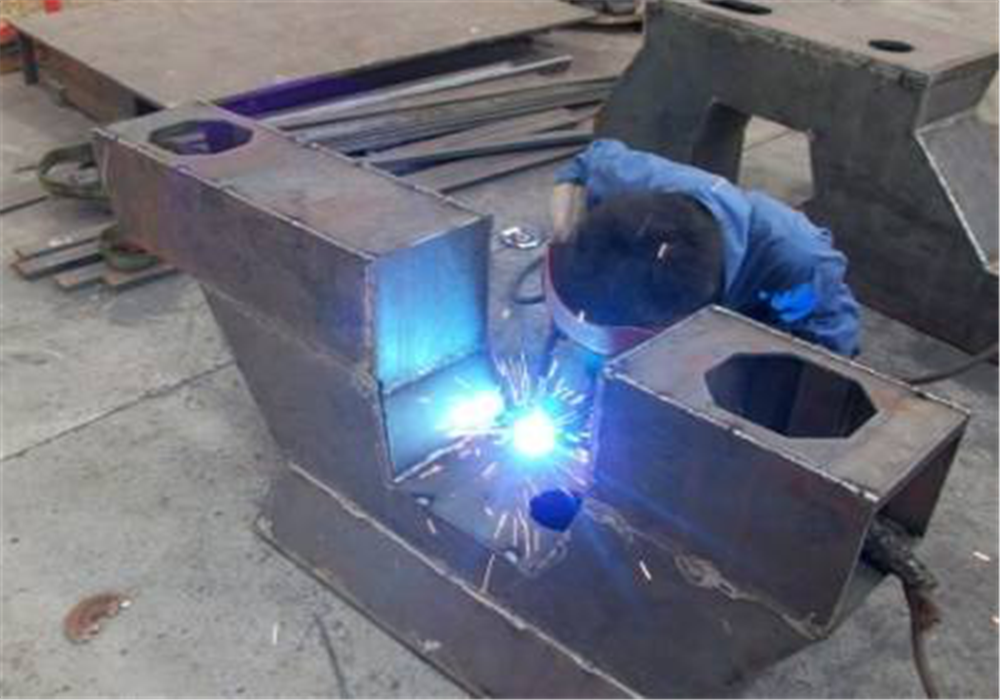

PLC |

Delta(Taiwan Brand) |

|

|

Electric components |

Schneider(France Brand) |

|

|

Plasma power source model |

Kjellberg SmartFocus400 |

|

|

Programming and nesting software |

FASTCAM (professional) |

|

|

Horizontal Servo Driving motor |

Panasonic AC servo motor(750W) |

|

|

Longitudinal Servo driving motor |

Panasonic AC servo motor(750W) |

|

|

Gear box |

Neugart(Germany Brand) |

|

|

Auxiliary Machinery By Buyer |

Voltage-stabilized source |

We will give requirements |

|

Air compressor |

||

|

Oil-water separator |

||

|

Foundations Made By Buyer |

Cutting table |

We will supply drawing |

|

H beam load bearing foundation |

||

|

Installation cement foundation |

||

|

Pedrail Channel |

3 Main Specification

|

Basic Parameter |

Effective cutting width |

2200mm |

|

Effective cutting length |

4000mm |

|

|

Plasma cutting thickness |

1-75mm |

|

|

Plasma cutting speed |

50-9000mm/min |

|

|

Cutting torch lifting distance |

200mm |

|

|

Idle running speed |

0-12000mm/min |

|

|

Speed setting error |

≤±5% |

|

|

Torch height controller accuracy |

≤±1.0mm |

|

|

Longitudinal line accuracy |

±0.2mm/10m |

|

|

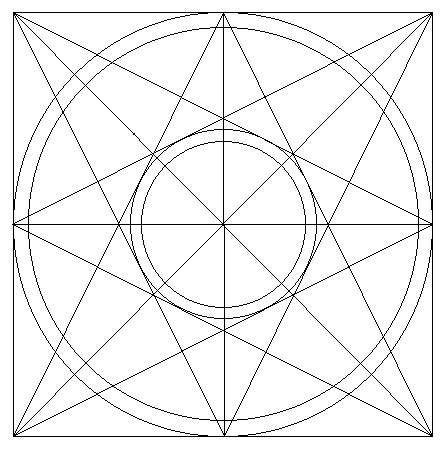

Accuracy Test |

Complete machine accuracy

(Subject to the right drawing)

Side length (Four sides)

1000mm x1000mm

Lineation speed,500-800mm/min

|

|

|

length of a side |

±0.5mm |

|

|

Diagonal error |AD-BC| |

±0.5mm |

|

|

Base point return error |

±0.2mm |

|

|

Intersection point error |

±0.5mm |

|

|

Lineation forward- reverse error |

±0.2mm |

|

|

Plasma Part |

Plasma power source |

Kjellberg SmartFocus400 |

|

Duty cycle |

100% |

|

|

Max output current |

400A |

|

|

Plasma source power |

116KW |

|

|

|

Machine weight |

3.2 ton |

|

|

Accelerated speed |

≥ 0.6m/sec2 |

|

Other Parameter |

Noise |

≤80 db |

|

|

Motor power |

Longitudinal and Horizontal 0.75 Kw 3set |

4 Working Requirement

|

Basic Requirement |

Supply power voltage/ frequency |

3 phase×380v±10%/50Hz

1 phase×220v±10%/50Hz

|

|

Ambient temperature |

-10℃-50℃ |

|

|

Relative humidity |

<90% no condensation |

|

|

Surroundings |

Ventilate |

|

|

Flame Cutting Requirement |

Gas type |

Propane / Acetylene |

|

Cutting oxygen pressure |

0.5-0.8 MPa |

|

|

Pre-heat oxygen pressure |

0.4-0.6MPa |

|

|

Gas pressure |

0.05-0.1 MPa |

|

|

Oxygen |

Purity: 99.5% |

|

|

|

Flow: 1.0m3/h |

|

|

Plasma cutting requirement |

Compressed air |

Dry, Oil free;

Flow: 400 scfh

Pressure: 8 bar

|

|

O2 |

Purity 99.5%; Dry, Oil free

Flow: 150 scfh

Pressure: 8 bar

|

|

|

N2 |

Purity 99.99%; Dry, Oil free

Flow: 410 scfh

Pressure: 8 bar

|

|

|

|

H35 |

Purity 99.995%; Dry, Oil free

Flow: 150 scfh

Pressure: 8 bar

|

5 Programming And Nesting Software (FastCAM Professional Version)

|

FastCAM is a powerful CAD plotting software specially used for number control cutting and it can read CAD DXF files and choose and output the NC files of different controllers; in addition, it can speed cutting obviously, heighten cutting quality and thus improve social and economic benefits. |

|

Plotting System |

|

Compatibility of plotting software |

|

Special functions to DXF files;

CAD clearing function;

CAD compacting function;

CAD extraction function;

CAD breaking and ranking functions.

|

|

Bridge function, including continuous bridge, break bridge and interruption bridge. |

|

Cutting Path |

|

Able to automatically or manually set cutting direction. |

|

Able to set cutting starting port, finishing point and cutting sequence. |

|

Able to set leadin and leadout. |

|

With the mid-layer function of CAD, able to set and conduct cutting, marking and drilling etc. |

|

Nesting System |

|

Able to nest quickly, continuously and automatically by placing hundreds of parts on many steel plates. |

|

Able to conduct optimized nestling on the rest steel plates. |

|

Able to manually interrupt AC automatic nestling and interfere with discharge. |

|

In the optimized nestling process, able to specify, revise and choose parts and have free horizontal movement, rotation and matrix etc. |

|

Verifying System |

|

Able to have analogue check and change to NC cutting files. |

|

Able to calculate material cost and processing cost. |

|

Able to support many controller NC codes and switch among different codes. |

|

Able to provide many languages that Windows platform supports. |

|

Printing: Discharging drawings and name, discharging parts list;

steel plate size, cutting speed, cutting time and steel plate utilization rate;

Programming parameters and number control codes.

|

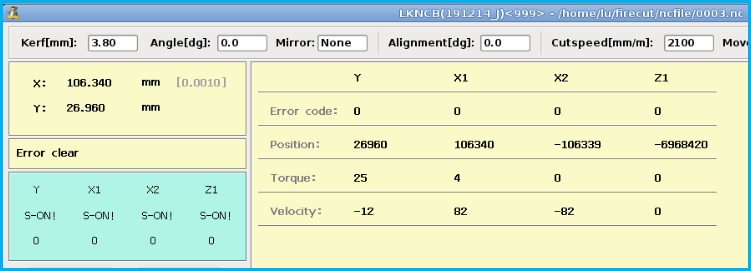

6 CNC Controller Details

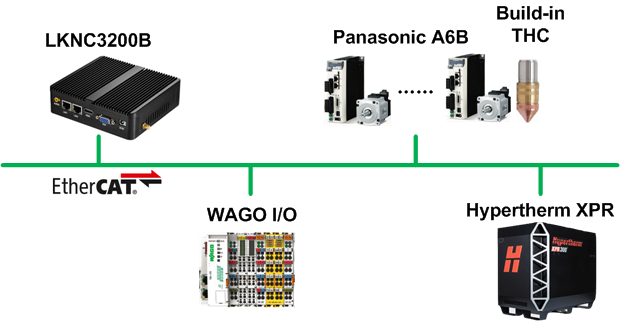

LKNC-3200B CNC (EtherCAT) Intro

The new CNC Cutting Control System LKNC-3200B is a field bus control system using industrial Ethernet (EtherCAT) based on 64-bit Linux real-time operating system. Instead of traditional motion control axis cards (PMAC) and complex wiring between CNC and servo drives, the new EtherCAT based CNC only uses a common network cable to connect multiple network servo drives in series. In addition, the digital serial communication method adopted by the network cable greatly enhances the anti-interference ability of motion signals and improves the accuracy.

In the Human-Machine-Interface (HMI), the new LKNC3200B continues the multi-task operation of the previous controller: during the process of part processing you can perform multiple operations, such as file editing, graphic changing, parts nesting, network transferring, parameter setting and cutting torch enabling. Equipped with a 19〞high resolution LCD touch screen, it has the characteristics of intuitive and user-friendly interface, easy and simple operation.

This system can also monitor the status of AC servo in real-time environment, and truly realize the control function of true bilateral and full feedback.

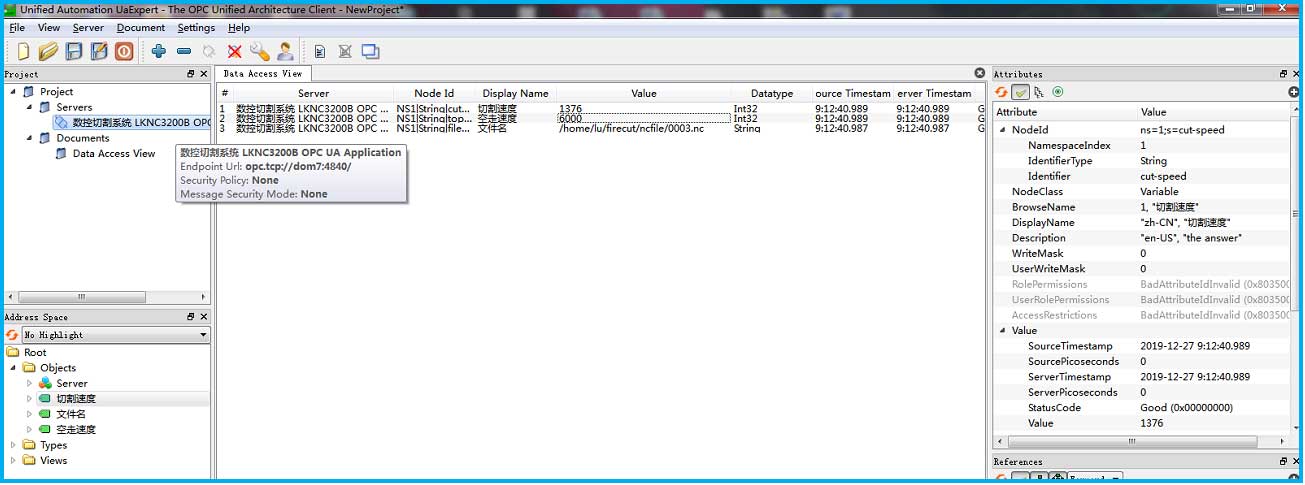

In terms of network, the system supports the mainstream industrial communication protocol OPU UA, which facilitates the access of equipment to the group control MES system of major manufacturers.

Specifications:

1. True bilateral, full feedback:

- oordinate absolute value and difference value of Double X axis are respectively reflected on the control interface

- The alarm information, absolute value, torque, speed, etc. of the motor are fed back to the controller

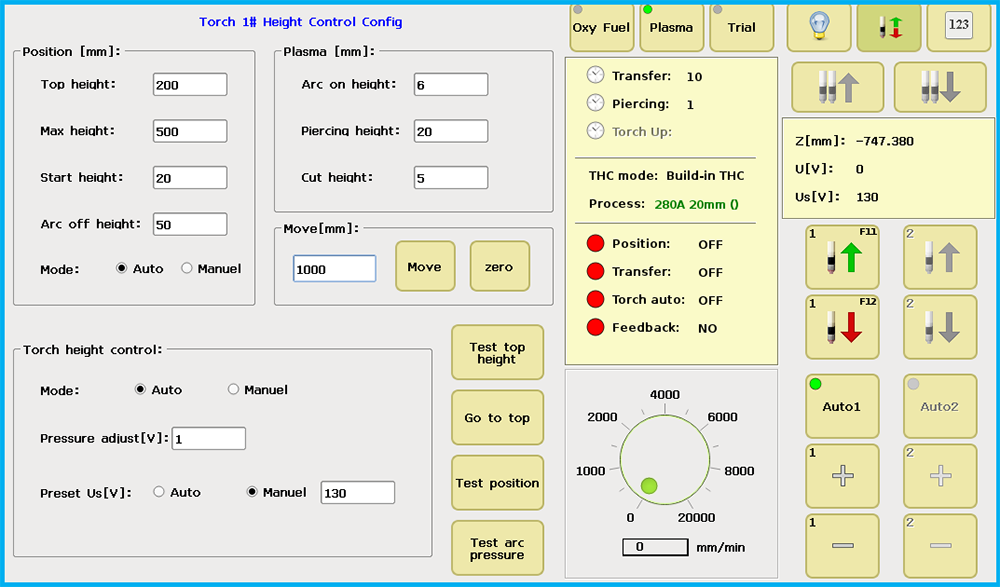

2. The built-in THC:

- Z axis as an independent axis, controlled by servo motor, more accurate and fast

- The communication mode of EtherCAT bus ensures 1ms arc voltage sampling period and height change during cutting

- The controller interface displays the current cutting torch height and arc pressure in real ti

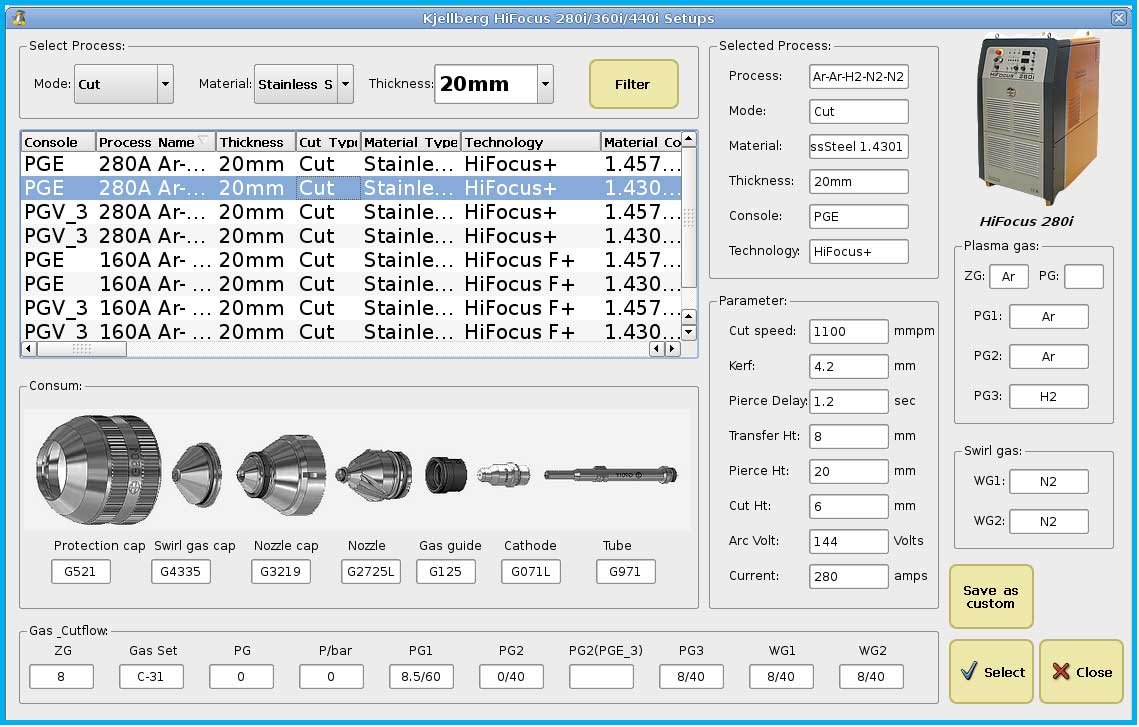

3. Integrate plasma processes:

- Main plasma power supplies such as Hypertherm,Thermal Dynamics, Kjellberg and ESAB

- Various processes, materials and up to 60 plate thicknesses are available

- Specially for Hypertherm XPR series plasma optimization and alarm log recording

- Record and count plasma consumables, and set the maximum piercing times and the maximum cutting length

4. Network function

- Cutting file transfer by LAN

- Remote control, monitoring or screen capture of mobile APP through wireless router

- Industrial communication protocol OPC UA: open communication protocol, collect and monitor cutting data in real time, cooperate with manufacturer to customize MES system, and realize enterprise group control operation

7 Affix Files List

|

Machinery manual |

1 set |

|

CNC system manual |

1 set |

|

Ac servo motor manual |

1 set |

|

Electricity and connection diagram |

1 set |

|

TAYOR inspection report |

1 set |

|

Packing list |

1 set |

|

Certification |

1 set |

|

Full sets of foundation drawing |

1 set |

8 Installation Terms

|

Seller personnel will supervise installation as following: |

|

1)Rail installation and assembly |

|

2)Positioning of machine and the work table |

|

3)Running of cables and hoses from service entry point |

|

4)Connection of electrical cables and gas hoses to the machine |

9 Training Terms

|

After the commissioning, Seller technician will commence Training. |

|

The customer shall provide sufficient material and consumables to ensure satisfactory completion to training. |

|

The training will comprise of the following things: |

|

1)Overview of machine |

|

2)Control features and operation |

|

3)Machine maintenance and adjustment |

|

4)Supervised running of machine |

|

The training of the machine operator is concurrent with the installation and commissioning, therefore personnel must be available at all times. |

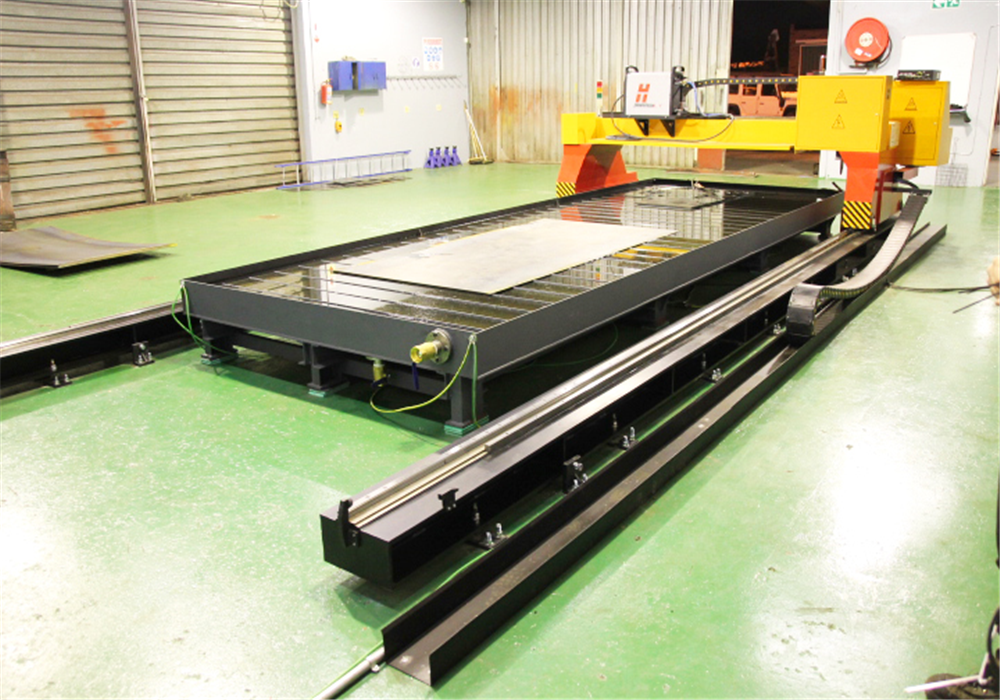

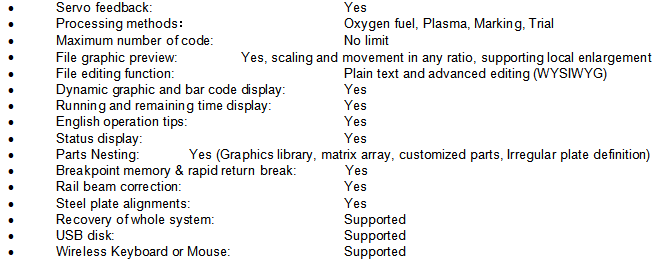

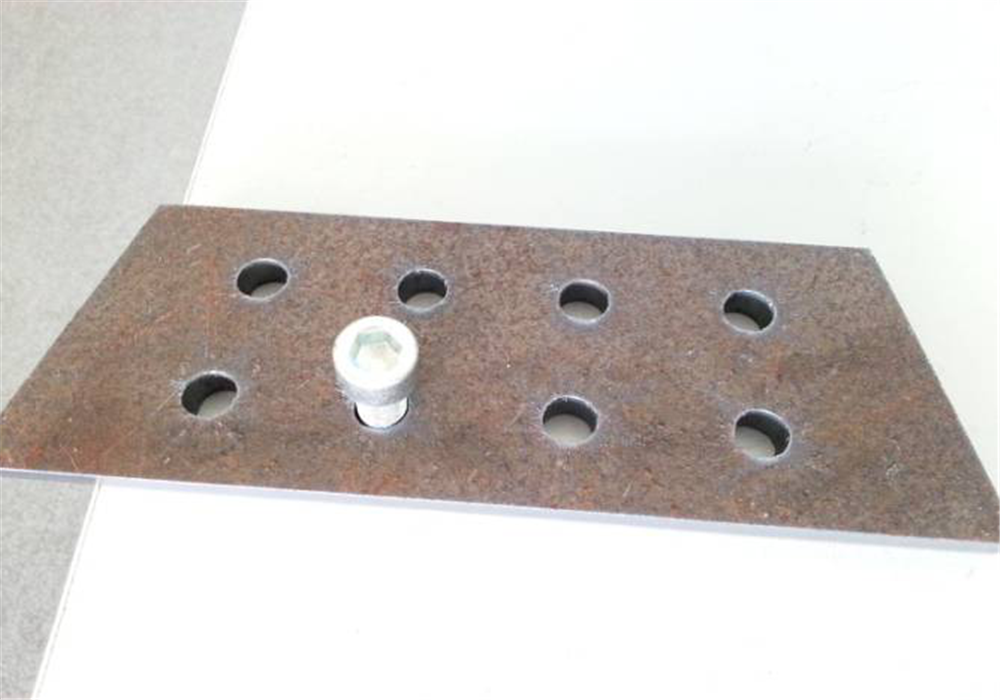

Machine Body Process

Box type welded structure, machine body is stable and heavy duty.

Machine body is processed by CNC planning machine and CNC milling machine, so machine body is with high accuracy.

Dual drive adopts symmetrical structure.

Excellent rigidity and intensity.

-

Box type welded structure

-

CNC Planing Machine

-

CNC Milling Machine

Machine Body Tempering And Painting

The whole machine body is processed by tempering, so our machine is very durable with very high accuracy.

Spray booth for machine painting.

-

Tempering Machine

-

Paint Spray Booth

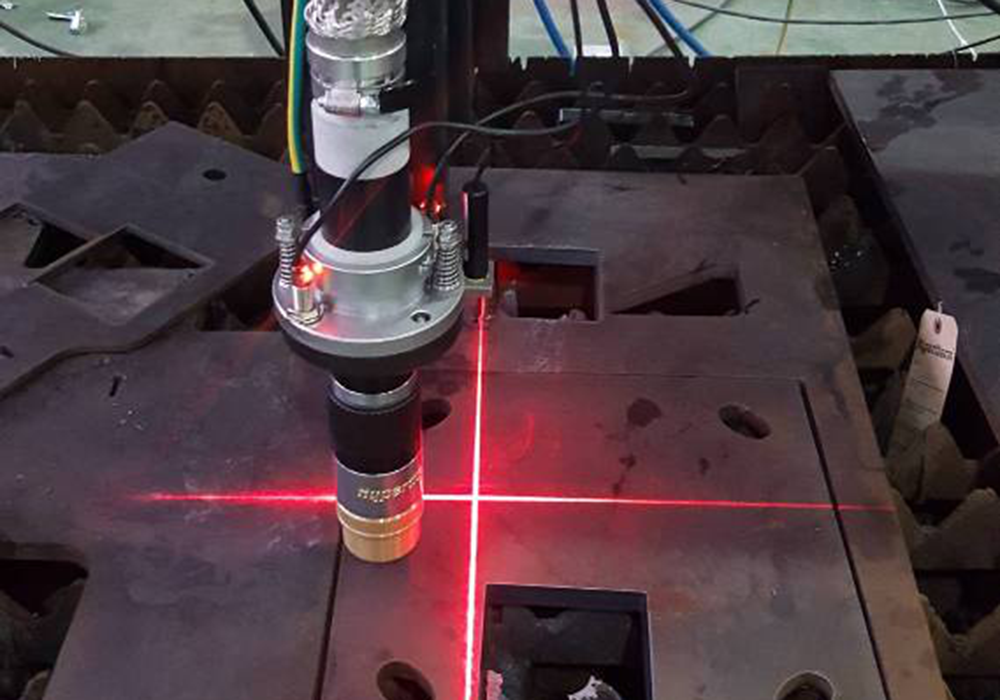

Laser Optic Alignment

-

-

-

Laser Optic Alignment To Guarantee Machine High Accuracy

Heavy Duty And Precision Machine Body

Heavy duty and precision machine body

Box weldment structure process tempering.

Excellent rigidity and intensity.

Dual drive adopts symmetrical structure.

-

Heavy Duty And Precision Machine Body(Double Drive)

Electrical Control Cabinet

-

Electrical Control Cabinet

-

AC Servo Drivers, PLC, Electrical Components

-

Schneider Electrical Components(France Brand)

-

Delta PLC(Taiwan Brand)

-

Schneider Electrical Components(France Brand)

Plasma Power Source

-

Germany SmartFocus400 Plasma Source

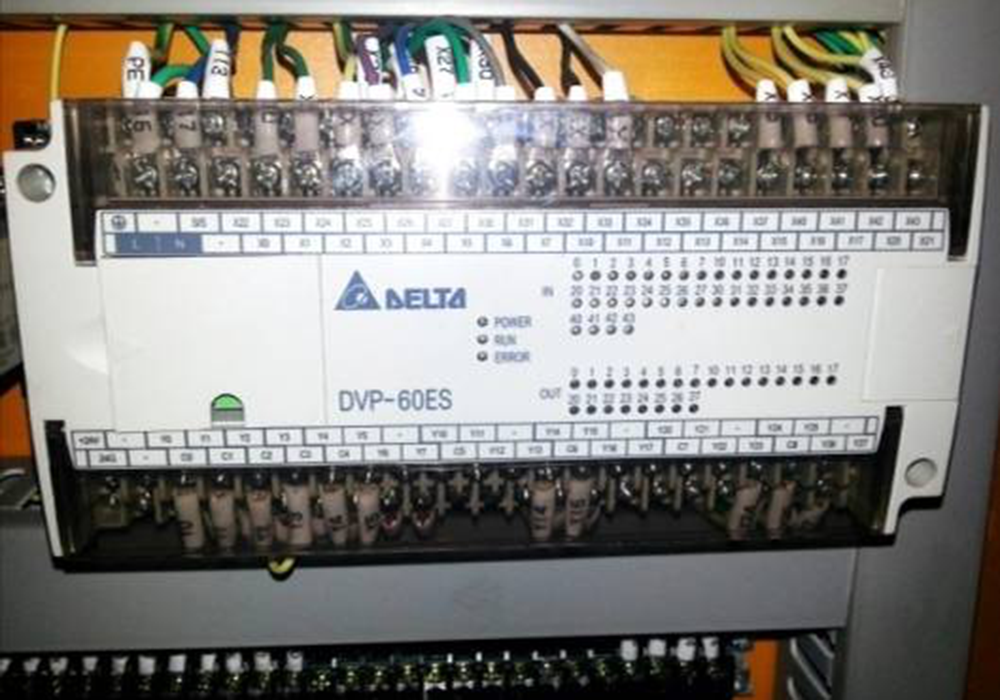

Torch Carrier and Torch

-

Plasma Cutting Torch

Plasma Anti-collision Device

-

-

-

360° Plasma Anti-Collision Torch Holder

Laser Point For Alignment

-

Laser Point For Plate Alignment

-

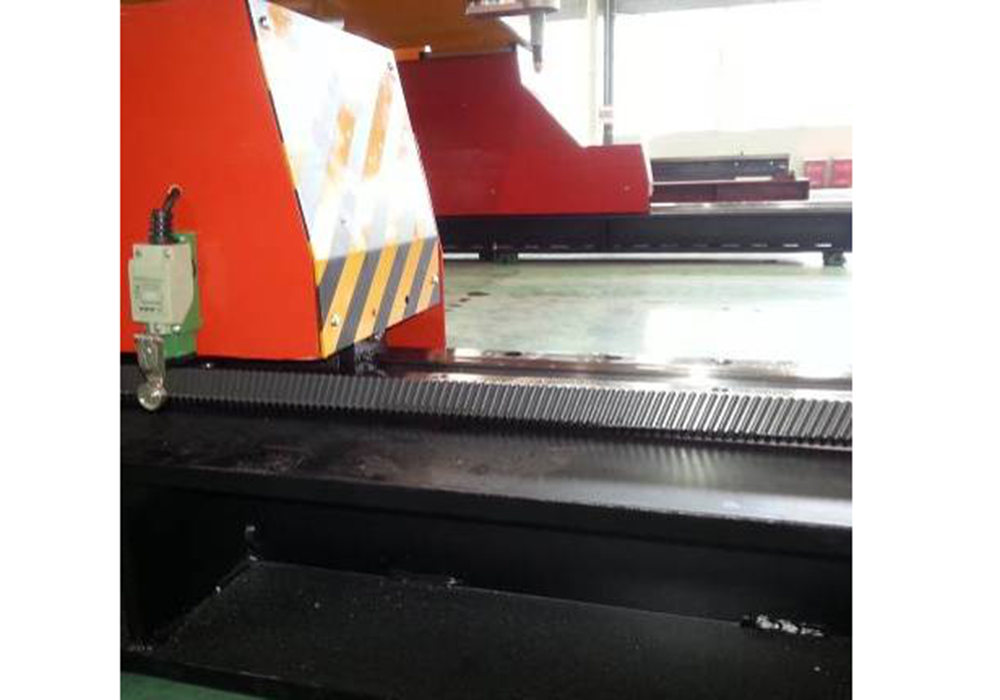

Transmission

-

Heavy Rail In Longitudinal Direction

-

Linear Guide In Horizontal Direction

Rail

Material: U71Mn

Intensity: No less than700N/mm²;

Loading capacity no less than = 10T(per meter),

Rail tensile strength no less than 883Mpa,

Compression strength no less than 1000T.

Process mode: High precision grinder.

Longitudinal rack accuracy: 7grade

Unit length: 1.0M

Pitch: CP6

Error: ±0.06mm/800mm

-

Accurate Grinding Rail

-

Auto Rail Clean Device

-

Auto Rail Clean Device

-

Auto Lubrication Device

-

Auto Lubrication Device

-

Helical Rack And Pinion Transmission

Helical rack and pinion transmission, which has high accuracy, can run at high speed

-

Helical Rack And Pinion Transmission

-

Closed Pedrail In All Axis

Closed Pedrail in all axis, which can protect piercing sparks and scraps getting into pedrail. It is good to gas hose, and safe to factory.

-

Closed Pedrail In All Axis

Ground Type Pedrail And Sky Type Pedrail

There are Ground Type and Skype Type Pedrail for customer's option.

-

Ground Type Pedrail Supply

-

Sky Type Pedrail Supply

Safety Devices

-

Emergency Button

-

Alarm Light

-

Limit Switch(Soft Stop)

-

Hard Stop

Water Table-Plasma Cutting Dust Collection(Option)

Water table for plasma cutting dust collection (made by user as per drawing from supplier)

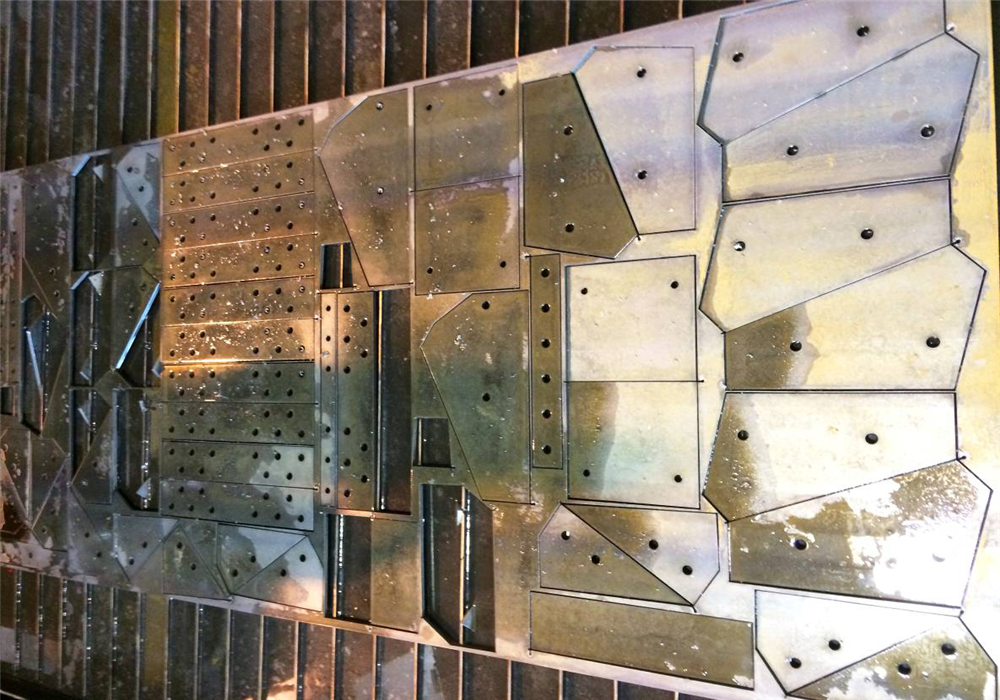

CNCSG Cutting Sample

-

-

-

CNCSG Cutting Samples

-

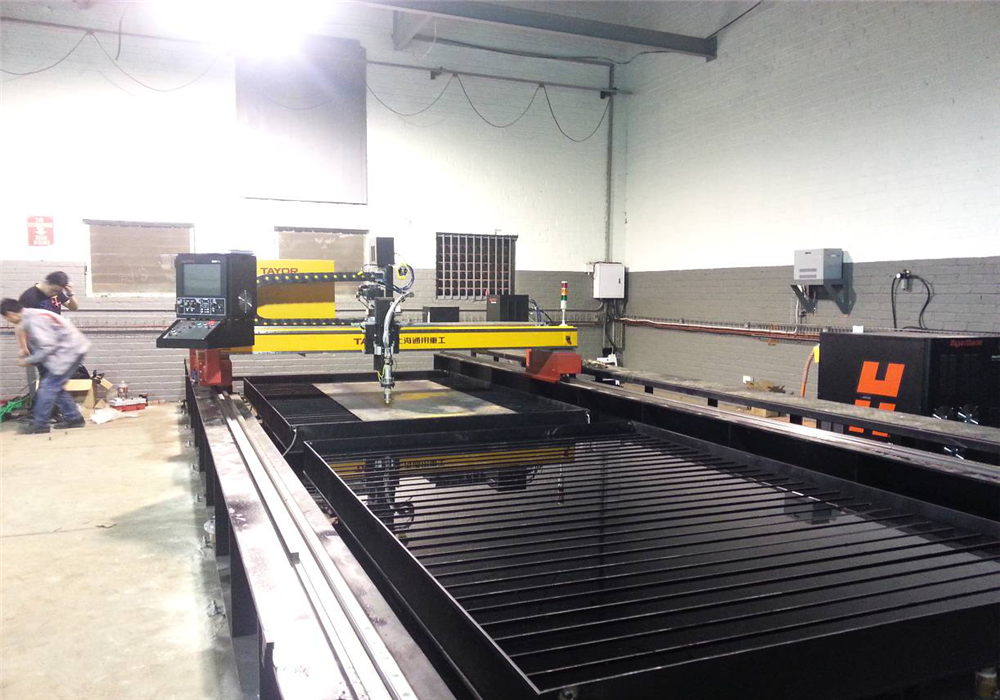

CNCSG In Customers' Factories

-

CNCSG In Customers' Factories

-

Other Machines In Customers' Factories

to be confirmed

to be confirmed

to be confirmed

to be confirmed

to be confirmed