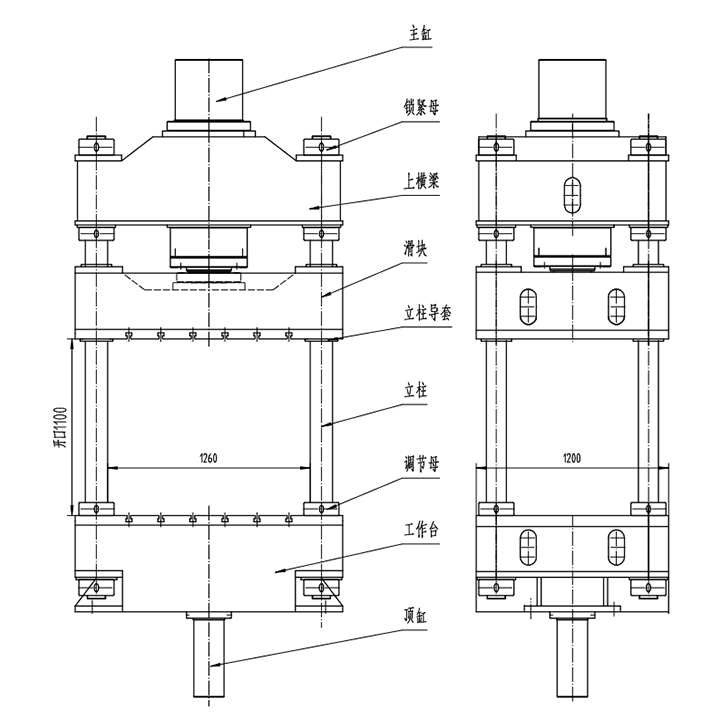

Hydraulic press machine (single cylinder) YAN32--200

1, Machine body: all machining by VMC machine center , making sure the high working accuracy

2, The four column all adopt 45 steel material , by forging making after quenching and chromium plating

3, The main cylinder rod making by forging process and adopt SKF seals , making sure lone use life

4, The hydraulic system and oil tank all design in the top of machine , easy operation

5, Working have jog /semi auto/automatic three mode with PLC control

6, Hydraulic and electrical all have overloading protection system

7, Water cooling system is standard features

8, The Press composed of main body and control devices which respectively formed with frame, main cylinder, knock-out cylinder, hydraulic system and drive mechanism, lower and upper limit switches pipe lines, electrical control cabinet and etc.

9, Drive mechanism includes oil tank, high pressure pumps, low pressure control system, valves, Electrical control system is designed according to the working procedure of hydraulic principle. By preset, sequential operation can be achieved by drive mechanism via pumps, cylinders, valves, tank and pipe lines.

10, The press is applicable to compression of plastic materials, For example, powder and plastics products forming and heat/cool metal extrusion, metal sheet drawing,stamping,bending, edge-folding, straightening, depressed mounting and etc.

Independent drive structures and electrical devices insure reliable operation with centered control buttons. Adjustment, manual operation and semi-automatic operation, three modes are provided respectively for your choice.

11, The working pressure, pressing speed, unload-descending speed and decelerated pressing speed can be respectively adjusted in reqirements.

12, By preset, knock-out, non-knock-out and drawing can be taken out with pressure-depentdent or distance-dependent movement of die. In the case of pressure-dependent movement, the main cylinder of YAN32 type press initiates pressure-holding, time delay and automatic return

13, or plastic, form products, it could put heating facilities on table & bottom surface of ram which is controlled by PID & DRO.

|

Model |

Unit |

|

|

|

Specification |

|

YAN32-200 |

|

|

Nominal force |

KN |

2000 |

|

|

Knock-out force |

KN |

400 |

|

|

Max.working hydraulic pressure |

Mpa |

25 |

|

|

Slide-stroke |

mm |

700 |

|

|

Knock-out stroke |

mm |

250 |

|

|

Max.Daylight |

mm |

1100 |

|

|

Slide speed |

Descent |

mm/s |

100 |

|

Working |

mm/s |

12 |

|

|

Return |

mm/s |

52 |

|

|

Effective area of table |

Left-right |

mm |

1000 |

|

Front-back |

mm |

900 |

|

|

Overall Size |

Left-right |

mm |

2825 |

|

Front-back |

mm |

2060 |

|

|

|

Height above grtound |

mm |

3725 |

|

Motor |

Kw |

11 |

|

|

WEIGHT |

T |

9.5 |

|

|

NO |

Name |

Supplier |

Remark |

|

1 |

Integrated Cartridge Valve |

Jining Taifeng |

|

|

2 |

Pilot Solenoid Valve |

Jining Taifeng |

|

|

3 |

High pressure oil pump |

China brand |

|

|

4 |

Motor |

China brand |

|

|

5 |

Contactless approximate switch |

OMRON |

|

|

6 |

Master button switch |

Schneider |

|

|

7 |

Pressure Gauge |

WUXI |

|

|

8 |

Miniature relay |

OMRON、Siemens、Schneider etc |

|

|

9 |

Controlling Transformer |

||

|

10 |

Auto air - breaker |

||

|

11 |

Seal |

SKF or DICHTOMATIK |

|

|

14 |

positioning sensor |

OMRON |

|

NO. |

Parts Name |

Qut. |

Unit |

Comments |

|

1 |

Seal Ring |

1 |

set |

|

|

2 |

Dust Ring |

1 |

set |

|

|

3 |

Combination of ring |

1 |

set |

|

|

4 |

Oil Filter |

1 |

pcs |

|

|

5 |

Lubricating Oil Gun |

1 |

pcs |

|

|

6 |

Wrench |

1 |

set |

Diameters 1-10mm |