Duct Manufacture Auto-Line Ⅲ

C: Duct Manufacture Auto-line Ⅲ

Line Ⅲ consists of a feeding metal frame, leveler grooving roller, hydraulic notch and punch square machine, hydraulic shearer and folder. The electrical control system uses a computer with a closed-loop servo-system to increase the precision and reliability of the line.

The maximum working speed is 10m/min. The length tolerance is +0.5mm. The diagonal line tolerance is +0.8mm.

The capacity of the manufacturing process will produce 1000m2 of square duct.

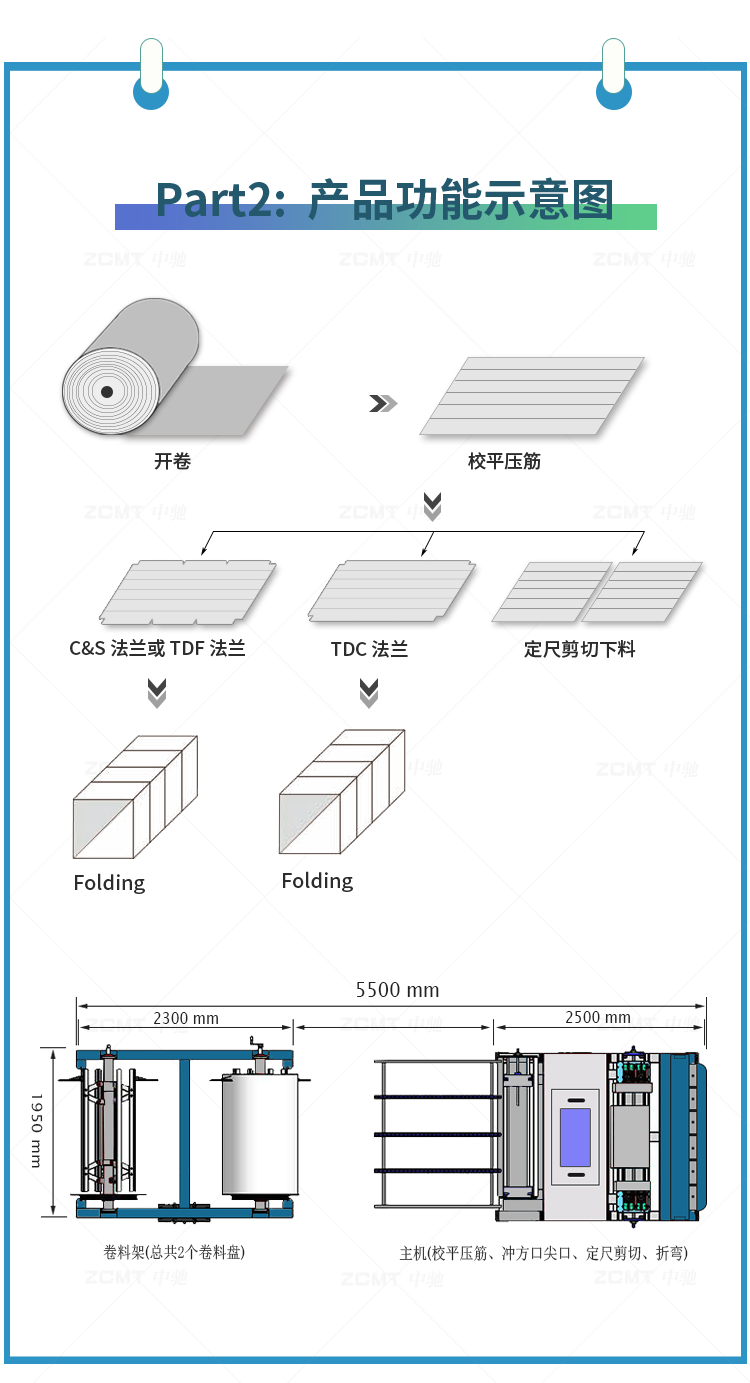

The work flow:

Coiler-Metal Feeder-Leveler Grooving Roller

notch and Punch Square Cut- fold--cutting metal for TDF

fold- cut feeding metal for insert flange

cut Feeding Metal for Duct

Duct Manufacture Auto-line Il

Note:

A: Fixed size cut metal that can be used with a plasma cutting machine.

B: A. punch "C" "S" insert cleat notch, which can be used with "C" cleat and "S" insert flange machine.

- Different connecting methods can be used with TDF flange machines and TDF connecting machines.

- It is able to punch all kinds of notch in angle steel flanges and "Z" shape flanges. It can also form"","”, and“" shape, and be used with a connecting machine to produce a complete set of ducts.

C: Able to punch TDC notch and press to form insert flange to produce“" shape duct; able to be used with connecting machine and insert flange to give

a complete set of ducts. can be used with plasma system.

|

Machine Dimensions (L.W.H) |

10500X2100X1500mm |

|

Machine total weight |

about 5T |

|

Material thickness |

0.4~1.2mm Galvanized steel & mild steel; 0.5~0.75mm stainless steel |

|

Max coil width |

1250mm (Option:1500mm) |

|

Products length |

Max:3000mm;Min 600mm |

|

High speed |

Max. 18m/min |

|

Length tolerance |

±0.5mm, |

|

Diagonal line tolerance |

±0.8mm |

|

Beading |

1-5 strips |

|

Voltage |

380V/3P/50 HZ |

A: Four power metal feeding frame

B: One leveler grooving roller machine

C: Four hydraulic notch and die

D: Hydraulic shearing and folding machine

E: Industrial computer and specific software