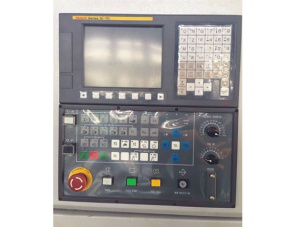

The machine adopts CNC system with function and high reliability .the machine design adopts machinical ,electronic and hydraulic integration method with compact structure.

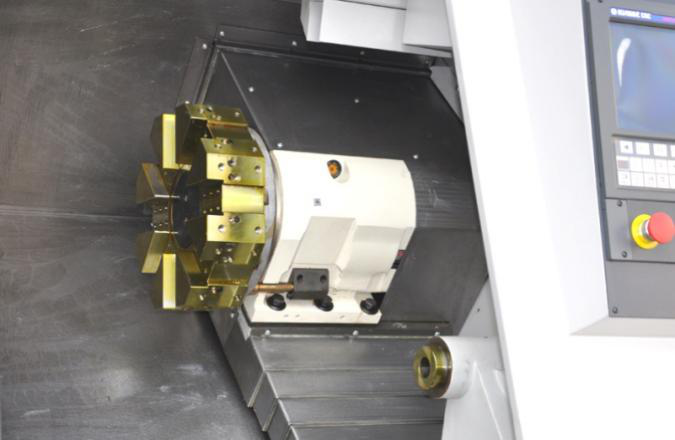

Flat bed and slant slide structure,with high rigidity and fluent chip removal.

X and Z axis adopt precision linear rolling guide with no blacklash to resulthigh rigidity and accuracy .

The spindle component is of high rigidity construction no preovide variable speed to relize constant linear speed cutting and high speed cutting .

Automatic centralized lubrication with full sufficency and reliability.

Full protection design,beautiful appearance and convenient operation and maintance.

Ball screws are pre-stretched to eliminate back play

X/ Z travel 180x420 mm, 7.5/11 kw main servo motor, 3000 rpm, 8-ways tool post station, chip conveyor, 1 GB program memory, 8.4" color LCD monitor, USB port, rigid tapping.

X and Z axes adopt precision linear guide with no backlash to result high rigidity and accuracy;

X/ Z travel 180x500 mm, 7.5/11 kw main servo motor, 3000 rpm, 8-ways tool post station, chip conveyor, 1 GB program memory, 8.4" color LCD monitor, USB port

|

MODELS |

CK25 |

CK-20B |

|

CAPACITY |

|

|

|

Max.cutting diameter for disc parts |

Ф250mm |

|

|

Max.cutting diameter for axle parts |

Ф420mm |

|

|

Max. swing over bed |

Ф500mm |

Ф410mm |

|

Max. turning over |

|

Ф200mm |

|

Max. turning diameter |

|

Ф360mm |

|

Max. cutting length |

500mm |

|

|

TRAVEL |

|

|

|

Max. cross travel(X) |

220mm |

180mm |

|

Max. longitudinal travel(Z) |

550mm |

420mm |

|

Guide ways X&Z |

Precision linear ball rail |

|

|

FEED |

|

|

|

Rapid feed for axis X |

12m/min |

12m/min |

|

Rapid feed for axis Z |

20m/min |

20m/min |

|

SPINDLE |

|

|

|

Max. speed of spindle |

4000rpm |

Ф200mm chuck: 3000rpm |

|

Spindle nose |

A2-6 |

A2-5 |

|

Diameter of spindle thru hole |

Ф65mm |

Ф56mm |

|

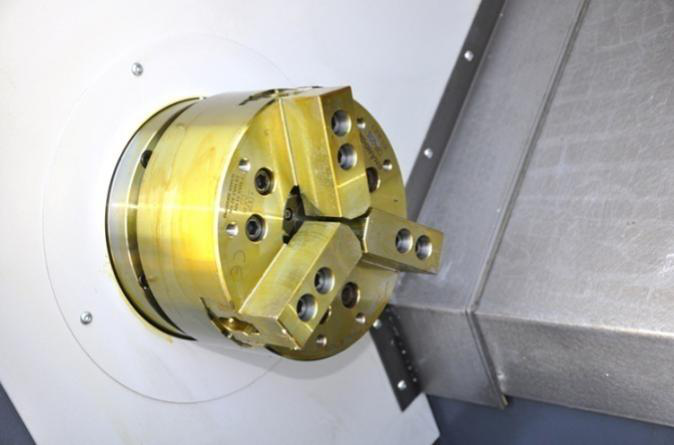

Hydraulic chuck |

8″ |

Ф160mm |

|

Spindle motor power |

11/15kw |

|

|

TOOL POST |

|

|

|

Tool number |

12 ways |

8 ways |

|

Outside diameter of cutting tool shank |

25×25mm |

25×25mm |

|

Inner dia. of cutting tool shank |

Ф40mm |

Ф32mm |

|

TAILSTOCK |

|

|

|

Tailstock sleeve dia. |

Ф80mm |

Ф63mm |

|

Tailstock sleeve travel |

100mm |

100mm |

|

Taper hole of tailstock quill |

M.T.No.4 |

M.T.No.4 |

|

OTHERS |

|

|

|

Main motor power |

|

Servo motor 11kw 380V |

|

Capacity for coolant |

120L |

100L |

|

Min.input |

0.001mm |

|

|

Bed structure |

45° slant bed integrated with stand |

60° slant bed |

|

Overall dimensions(L×W×H) |

3712×1660×1850mm |

2435×1270×1660mm |

|

Net weight |

4500kg |

2700kg |

-

Fanuc 0i TF(5) cnc system

-

3,000-rpm spindle

-

Turret: 8-Station Hydraulic Turret

-

Workholding: 8" Closed Hydraulic 3-jaw Chuck, Ф170mm spindle nose

-

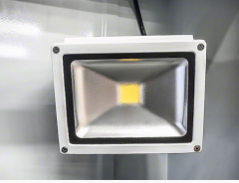

This LED work light provides bright illumination of the work area for part inspection, job setup, and changeovers.

-

Standard Program Memory, 1 GB

-

12-month limited warranty covering defects in material and workmanship.An additional 1-year extended warranty may be purchased at any time before the original warranty expires.

-

System;both local and foreign brands control systems can be adopted according to customer's requirement. For example SIMENS, GSK, FAGOR...

-

Turret;Hydraulic ,servo, or electric tool post can be selected according to customers' requirement. FANUC servo motor for Spindle motor USD1600.00

-

Working hold;Hydraulic solid chuck is standard and Hydraulic hollowed chuck can be selected,200mm USD750.00

-

Tailstock;accoding to customer's requests,Hydraulic and programmable tailstock can be selected.

-

Renishaw tool setter

-

Auto Chip Conveyor; quick, high-volume chip removal for increased productivity USD1500.00

-

Sleeve spindle (Taiwan brand) with 5000rpm USD2500.00

-

DH-65 S2 bar feeder USD4950.00

-

DH-65L S2 bar feederUSD5500.00

|

CK25 dimension (L x W x H) |

Shipping dimension (L x W x H) |

Net Weight |

|

1950x1650x1680mm |

3500x1810x2110mm |

3400kg |

This document provides the weight and shipping dimensions. The weight listed for a machine may be off by as much as +/- 5% due to option selection, casting variations, and even the moisture content of the wooden crates surrounding the machine.