Flat Bed CNC Lathe Machine

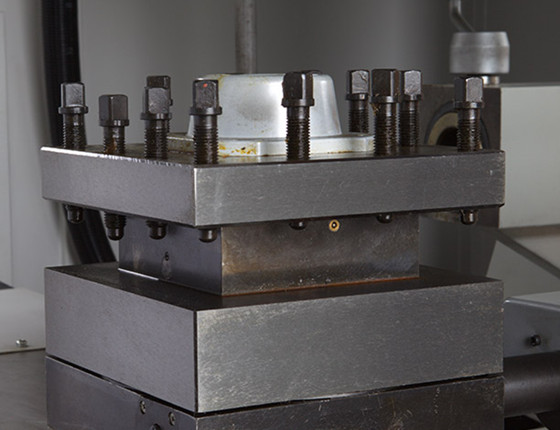

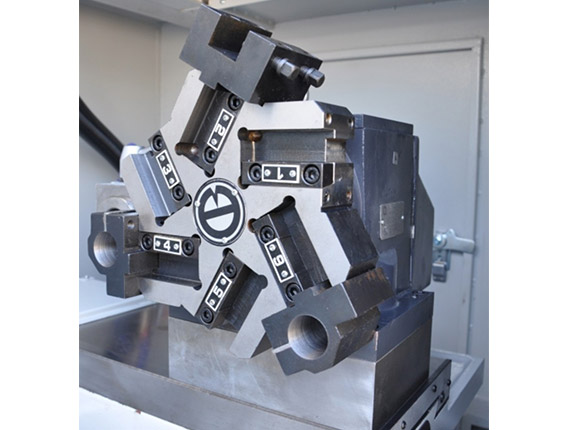

Either vertical or horizontal 4-station or 6 station tool post as well as gang tool can be selected.The post is located on precision contrite gears with a high repeated positioning accuracy.

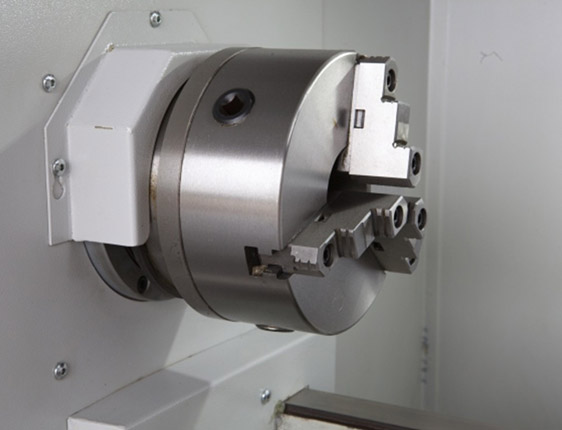

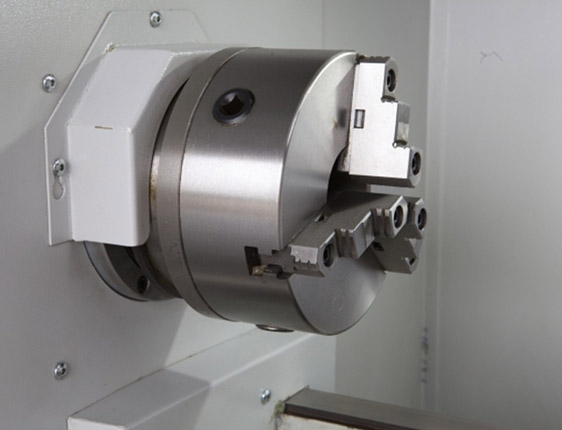

Both chuck and tailstock are available with hydraulic or manual or pneumatic type.

The surface of the bedways is supersonic frequency hardened and precision ground with a long service life.

X/ Z travel 320/720-2970mm,spindle boreФ80mm ,7.5kw main servo motor, 27-1630rpm, 4-stations or 6-stations , X rapids 8m/min,Z rapid 10m/min 1 GB program memory, 8.4" color LCD monitor, USB port, rigid tapping.

|

Item |

Unit |

CK6140 |

CK6150 |

CK6161 |

CK6166 |

CK6180 |

|

Guideway width |

mm |

400 |

||||

|

Max. swing dia. over bed |

mm |

Φ400 |

Φ500 |

Φ610 |

Φ660 |

Φ800 |

|

Max. swing dia. over slide |

mm |

Φ210 |

Φ300 |

Φ370 |

Φ400 |

Φ540 |

|

Max. workpiece length |

mm |

750/1000/1500/2000/3000 |

||||

|

Max. workpiece weight |

kg |

300 |

||||

|

Spindle bore |

mm |

Φ52(Opt.:Φ80/Φ104) |

||||

|

Spindle taper |

/ |

MT6#(spindle bore Φ52); |

||||

|

Φ90 1:20(spindle bore Φ80); |

||||||

|

Φ113 1:20(spindle bore Φ104) |

||||||

|

Spindle speed |

rpm |

Independent spindle:100~1600;3 class gears:21~150,66~500,162~1500 |

||||

|

Spindle head type |

|

C6(spindle bore Φ52);D8(spindle bore Φ80,Φ104) |

||||

|

Chuck size |

/ |

8’’/10’’ |

||||

|

Spindle motor |

kw |

7.5 |

11 |

|||

|

X axes travel |

mm |

250 |

260 |

320 |

340 |

410 |

|

Z axes travel |

mm |

600/850/1350/1850/2850 |

||||

|

X/Z axes ball screw O.D. |

mm |

25/50 |

||||

|

X/Z axes positioning accuracy |

mm |

±0.015 |

||||

|

X/Z axes repositioning accuracy |

mm |

±0.006 |

||||

|

X/Z axes rapid rate |

m/min |

4月6日 |

||||

|

Toolshank size |

mm |

25×25 |

||||

|

Tailstock quill travel |

mm |

150 |

||||

|

Tailstock quill dia. |

|

Φ75 |

||||

|

Tailstock quill taper |

/ |

MT5# |

||||

|

Turning accuracy |

/ |

IT6-7 |

||||

|

Turning roughness |

μm |

Ra1.6 |

||||

|

Turning roundness |

mm |

0.005 |

||||

|

Turning flatness |

mm |

0.025/300 |

||||

|

Overall size |

mm |

2550×1550×1700(for 750mm) |

2550×1550×1900(for 750mm) |

|||

|

2750×1550×1700(for 1m) |

2750×1550×1900(for 1m) |

|||||

|

3250×1550×1700(for 1.5m) |

3250×1550×1900(for 1.5m) |

|||||

|

3700×1550×1700(for 2m) |

3700×1550×1900(for 2m) |

|||||

|

4700×1550×1700(for 3m) |

4700×1550×1900(for 3m) |

|||||

|

N.W./G.W. |

Kg |

2100/2300 |

2200/2400 |

2250/2450 |

2300/2500 |

2400/2600 |

|

(750/1000/1500/2000/3000mm) |

|

2200/2400 |

2300/2500 |

2400/2600 |

2450/2650 |

2550/2750 |

|

2300/2600 |

2400/2700 |

2600/2900 |

2650/2950 |

2750/3050 |

||

|

2700/3100 |

2800/3200 |

2850/3250 |

2900/3300 |

3000/3400 |

||

|

3500/4100 |

3600/4200 |

3650/4250 |

3700/4300 |

3800/4400 |

||

-

Fanuc system Oi MF(5)

-

1630-rpm spindle

-

Turret: 4-Station Bolt-On Tool Turret;

-

Workholding: Manual Chuck, A2-8 spindle nose

-

Coolant system: Coolant Tank with 90w pump

-

This work light provides bright illumination of the work area for part inspection, job setup, and changeovers. The light is operated via a manual switch.

-

Standard Program Memory, 1 GB

-

Siemens System or other CNC controlers as requirement

-

Turret;6 station ,vertical or horizontal turret can be seleted,Gang tool post is also optional.

-

Manual Tailstock, MT5 manual quill

-

Working hold; Hydraulic hollowed chuck can be selected

-

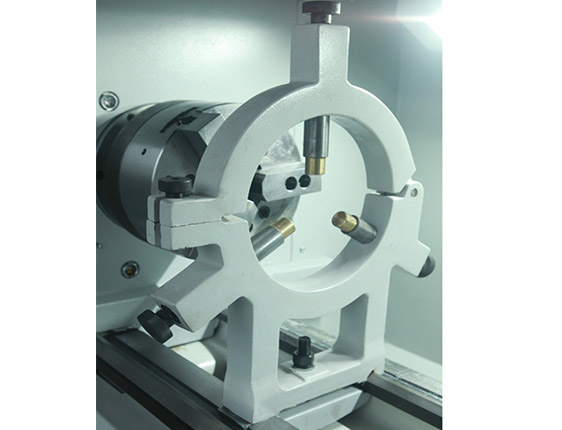

Manual Steadyrest; manual positioning and gripper adjustment; three-point contact rollers with open C-frame.

-

Doorlock; This is guarantee the door closed when the spindle is running.

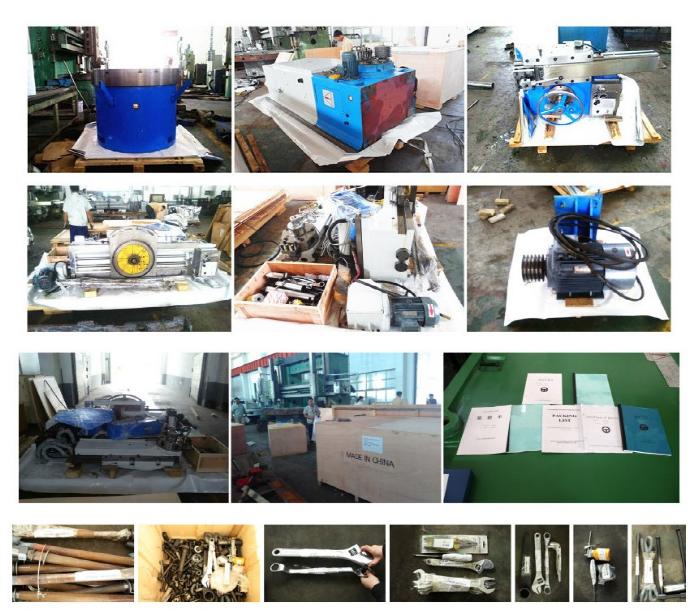

1、FANUC digital AC spindle and servo motors

2、Hydraulic power unit

3、Hydraulic chuck

4、Electric bi-directional electric turret

5、Coolant supply system

6、Lubrication unit

7、Operation & maintenance manual

8、Machine electric drawings

9、General tools

10、Levelling bolts and plates