CNC Vertical Lathe Machine

(1). Workbench base: The workbench base material is HT250. The workbench base is annealed by thermal aging stress relief. The design of the base adopts symmetrical reinforcement technology to ensure the stability of the equipment foundation.

(2). Bed: The bed is made of HT250, which is annealed by thermal aging and stress relief. The guide rail of the bed has been quenched with HRC50 or above, and ground after quenching. The machining accuracy is 0.02 / 1000mm, and the total length is 0.02mm. The bed and the workbench base fit together. The bed design is mature and stable, and has sufficient rigidity.

(3). Beam lifting: The beam lifting adopts the turbine lifting and T-screw lifting mechanism. There is a hydraulic locking mechanism on the beam. It is clamped by a hydraulic lever wedge block mechanism with a self-locking function. Tight on the post. The upper and lower cross beams are equipped with double mechanical limit and electrical soft limit, which is safe and reliable.

(4). Beam: The beam is made of HT250, which is annealed by heat aging and stress relief. The beam processing accuracy is 0.02 / 1000mm, and the total length is 0.02mm. Beam guide rails are quenched with HRC50 or above, and ground after quenching. The horizontal ball screw (X axis) of the beam adopts Nanjing craftsmanship P3 class heavy-duty advanced product, and the screw support adopts imported high-precision bearings for screw, which has the characteristics of high precision, high rigidity and precision. The X-axis servo motor is decelerated by the planetary reducer to increase the torque, and then connected to the ball screw through an elastic diaphragm coupling. The planetary reducer is a Newt Dart precision type. The appearance of the beam is made of white steel protective cover, which is beautiful and elegant.

|

No. |

Name |

unit |

CK5112D |

|

1 |

Table diameter |

mm |

1000 |

|

2 |

Max. turning diameter |

mm |

1250 |

|

3 |

Max. working height |

mm |

1000 |

|

4 |

Max. weight of work-piece |

T |

3.2 |

|

5 |

Cutter arbor section dimension |

mm |

30×40 |

|

6 |

Max. cutting resistance of railhead |

N |

20000 |

|

7 |

Max. torque of table |

N·m |

25000 |

|

8 |

Speed-step of table |

|

4 gears stepless |

|

9 |

Speed range of table |

r/min |

6.3-200 |

|

10 |

Horizontal travel of railhead |

mm |

700 |

|

11 |

Vertical travel of railhead |

mm |

650 |

|

12 |

Feed range of railhead |

mm/min |

0.1-1000 |

|

13 |

Feed steps of railhead |

|

stepless |

|

14 |

Rapid traveling speed of railhead |

mm/min |

2000 |

|

15 |

Max. travel of crossbeam |

mm |

650 |

|

16 |

Speed of crossbeam |

mm/min |

440 |

|

17 |

Main motor power |

Kw |

22 |

|

18 |

Beam lifting motor power |

Kw |

2.2 |

|

19 |

CNC axes |

|

X\Z |

|

20 |

CNC system |

|

Siemens 828D |

|

21 |

Positioning accuracy |

mm |

0.03 |

|

22 |

Repeated positioning accuracy |

mm |

0.015 |

|

23 |

Machine weight(approx.) |

T |

8.5 |

|

24 |

Machine overall dimension(approx.) |

mm |

2360*2277*2800 |

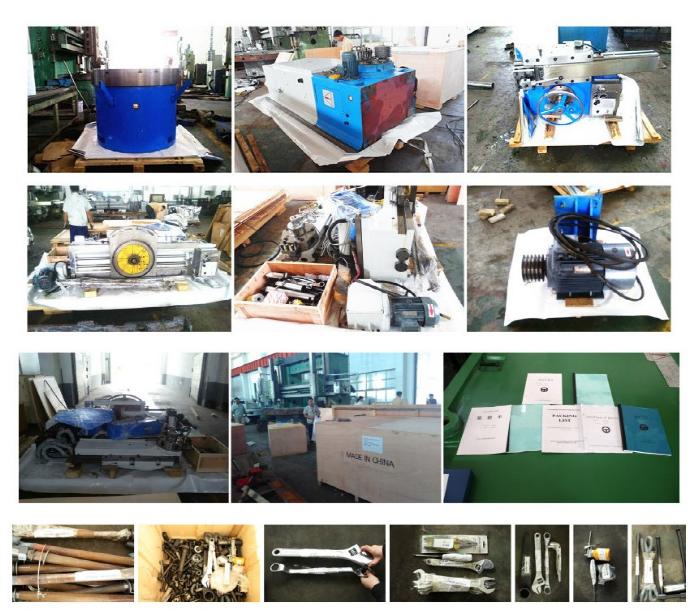

| No | Name | Quantity |

|

1 |

foundation leveling bases with foot screws, nuts, gaskets |

7 |

| 2 |

chuck jaw |

4 |

| 3 |

tool holders |

1 |

| 4 |

working lamp |

1 |

| 5 |

technical documents (operation manuals,etc) |

1 |

| 6 |

accuracy test report |

1 |