Internal Grinding Machine

This machine is a plain internal grinder capable of grinding cylindrical and conical through holes or blind holes of various of mechanical workpieces in single piece or small batch producttion .the grinding wheel of the machine is made for cross feed ,while the worktable for longititudinal reciprocating movement .

The cross feed of the grinding wheel is performed either manually or hydraylically . In case of hydraylic feed , the wheel makes a fine feed motion(i.e. periodic feed ) with each reciprocation of the table . the feed increment can be adjusted steplessly .

The feed system is provided with a jumping mechanism ,with which the grinding wheel can take the jump-in and jump-out movements .wheel dressing is carried out at the fixed position with the grinding wheel jumped out ,while grinding is performing at the place the grinding wheel jumps in . the feed termination is set by means of a dead stop which offers a high repeatable positioning accuracy in sizematic grinding in batch production

There are two driving chains in feed system : one is used for grinding and the other for adjustment and dressing feed . they are not interfered with each other . during grinding , the handwheel doesn’t advance or retract frequently

and the operator doesn’t have to remember the position of the graduation disc so that it is easy to make adjustment and operation .

The longitudinal reciprocating movement of the table is friven hydraulically and its speed can be varied steplessly . the fast advance and retract positions of the table and the table speeds in grinding and dressing can be set through operatuib and adjustment .

The speed of workhead spindle can be varied steplessly by a thyristor converter for DC drive. The electrical control equipment is centralized in the electrical cabinet with control pushbuttons .etc on its panel for easy operation .

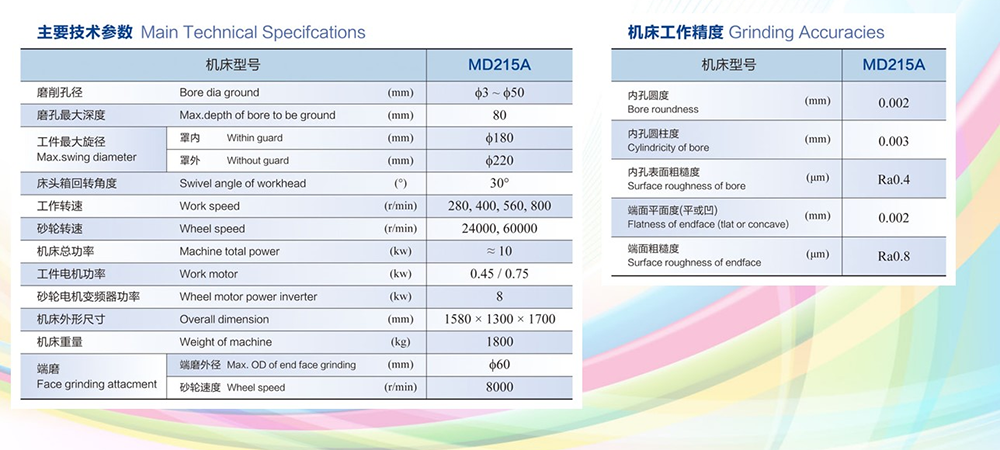

| Model |

M2110C |

MD215A |

|

Grinding diameter |

Ø6-Ø100mm |

|

|

Maximum grinding depth |

150mm |

|

|

Rotating diameter of workpiece with cover |

Ø260mm |

|

|

Rotating diameter of workpiece without cover |

Ø480mm |

|

|

Headstock spindle maximum load-bearing |

50kg |

|

|

Maximum travel of working table |

550mm |

|

|

Headstock maximum turning angle |

20° |

|

|

Rotational speed of workpiece |

180,250,355,500rpm |

|

|

Speed of grinding wheel spindle |

10000/18000/24000rpm |

|

|

Working table speed |

0.1~8m/min |

|

|

Maximum travel of feeding slide |

80mm |

|

|

Feeding rate of feeding handwheel per rotation |

0.32mm |

|

|

Feeding rate of feeding handwheel per grid |

0.002mm |

|

|

Adjusting handwheel per rotation |

0.01mm |

|

|

Adjusting handwheel per grid |

2mm |

|

|

Power of workpiece motor |

0.45/0.75kw |

|

|

Power of grinding wheel motor |

2.2kw |

|

|

Power of hydraulic motor |

0.75kw |

|

|

Power of cooling motor |

0.09kw |

|

|

Power of end face grinding motor |

0.75kw |

|

|

Dimension |

2363*1260*1650 |

|

|

Weight |

2550kg |

|

| Roundness 0.003 Cylindricity 0.005 Roughness Ra0.32 | ||

|

S/N |

Name |

Specification |

Qty |

Remark |

|

1 |

Internal Grinder |

M2110C |

1 Set |

|

|

2 |

Cooling Device |

130/Y112-70 |

1 |

|

|

3 |

Grinding device |

SJ6-25/1 |

1 |

Accessories Box |

|

4 |

Grinding device |

SJ10-25/1 |

1 |

Accessories Box |

|

5 |

Three Jaw Chuck |

Ø160 |

1 |

Mounted On Machine |

|

6 |

Special Greases |

|

500g |

Accessories Box |

|

7 |

Chuck Wrench |

9006 |

1 |

Accessories Box |

|

8 |

V-belt |

Type A,800 |

1 Piece |

Accessories Box |

|

9 |

Endless Rubber Nylon Belt |

1.5*50*1050 |

1 Piece |

Accessories Box |

|

10 |

Bush |

9002 |

2 |

Accessories Box |

|

11 |

Flange |

9001 |

1 |

For Mounting Chuck |

|

12 |

Outer Hexagonal Bolts |

M8*25 |

3 |

For Tightening Chuck |

|

13 |

Inner Hexagonal Bolts |

M10*-25 |

3 |

For Tightening Flange |

|

14 |

Joint Shaft Assembly |

3901 |

1 |

Accessories Box |

|

15 |

Joint Shaft Assembly |

3902 |

1 |

Accessories Box |

|

16 |

Joint Shaft Assembly |

3904 |

1 |

Accessories Box |

|

17 |

Joint Shaft Assembly |

3905 |

1 |

Accessories Box |

|

18 |

Joint Shaft Assembly |

3906 |

1 |

Accessories Box |

|

19 |

Belt Pulley |

Ø75*60 |

1 |

Mounted On SJ10-25/1 |

|

20 |

Belt Pulley |

Ø30*60 |

1 |

For SJ6-25/1 |

|

21 |

Belt Pulley |

Ø40*60 |

1 |

For SJ6-25/1 |

|

22 |

Puller Screw |

23/SJ6-25 |

1 |

For SJ6-25/1 |

|

23 |

Puller Screw |

23/SJ10-25 |

1 |

For SJ6-25/1 |

|

24 |

Wheel Recessed One Side |

PDA17*20*5 |

1 |

Accessories Box |

|

25 |

Wheel Recessed One Side |

PDA25*25*6 |

1 |

Accessories Box |

|

26 |

Wheel Recessed One Side |

PDA70*40*20 |

1 |

Accessories Box |

|

27 |

Parallel Grinding Wheel |

P45*35*16 |

1 |

Accessories Box |

|

28 |

Parallel Grinding Wheel |

P30*26*10 |

1 |

Accessories Box |

|

29 |

Operational Instruction |

|

1 Each |

Accessories Box |

|

30 |

Certificate Of Conformity |

|

1 Each |

|

|

31 |

Packing List |

|

1 Each |

|

|

32 |

Work Table Cover |

280*323*83 |

1 |

Inside The Machine |

|

No |

Name |

Unit |

Qty |

|

1 |

Joint disc |

Piece |

1 |

|

2 |

Single-ended wrench |

Piece |

1 |

|

3 |

Single-ended wrench |

Piece |

1 |

|

4 |

Wrench |

Piece |

1 |

|

5 |

Wrench |

Piece |

1 |

|

6 |

Three-jaw universal chuck |

Piece |

1 |

|

7 |

Back grinding apparatus |

Set |

1 |

|

8 |

Front grinding apparatus |

Set |

|

|

9 |

Front grinding apparatus |

Set |

1 |

|

10 |

Crank wrench |

Set |

1 |

|

11 |

Grinding wheel chuck |

set |

1 |

|

set |

1 |

||

|

set |

1 |

||

|

set |

1 |

||

|

12 |

Straight grinding wheel |

Piece |

1 |

|

Piece |

1 |

||

|

13 |

V-grinding wheel |

Piece |

1 |

|

Piece |

1 |

||

|

14 |

Belt (flat ) |

Piece |

1 |

|

Piece |

1 |

||

|

15 |

Belt (V) |

Piece |

1 |

|

Piece |

1 |

||

|

16 |

Endless rubber cotton belt |

Pair |

1 |

|

V-belt |

Pair |

3 |

|

|

17 |

Screw |

Piece |

1 |

|

18 |

Disassembly screw |

Piece |

1 |

|

Piece |

1 |

||

|

19 |

Screw |

Piece |

1 |

|

20 |

Disassembly screw |

Piece |

1 |

|

21 |

Cooling equipment |

|

1 |

|

Name |

Amount |

Remark |

|

Operational instruction |

1 |

Accessory box |

|

Test certificate |

1 |

Accessory box |

|

Packing list |

1 |

Accessory box |